5 Technological Advantages of Laser Cutting: Redefining Automotive Production Efficiency

Publishing time.

Oct 11,2025

Application of Laser Cutting Machines in the Automotive Industry: Driving Precision and Efficiency

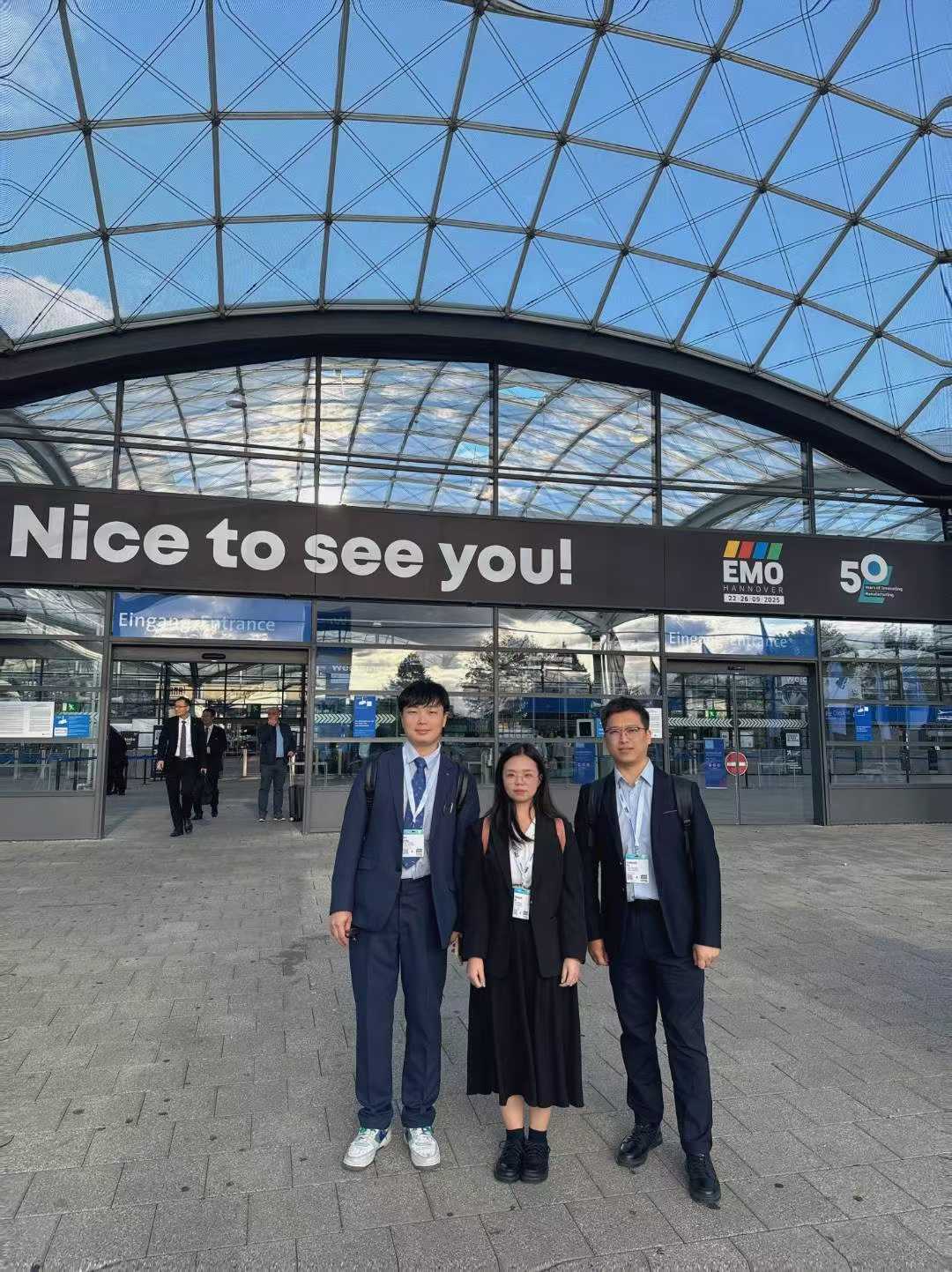

In the fast-paced world of automotive manufacturing, where precision, efficiency, and innovation are paramount, laser cutting machines have emerged as a transformative technology. From body-in-white (BIW) production to intricate component fabrication, these advanced tools are redefining how automakers approach material processing, enabling lighter, safer, and more sustainable vehicles. This article explores the key applications, technological advantages, and future trends of laser cutting in the automotive sector.

1. Core Applications of Laser Cutting Machines in Automotive Manufacturing

Laser cutting technology has penetrated nearly every stage of automotive production, addressing the industry’s demand for high accuracy and flexible processing. Below are its most critical use cases:

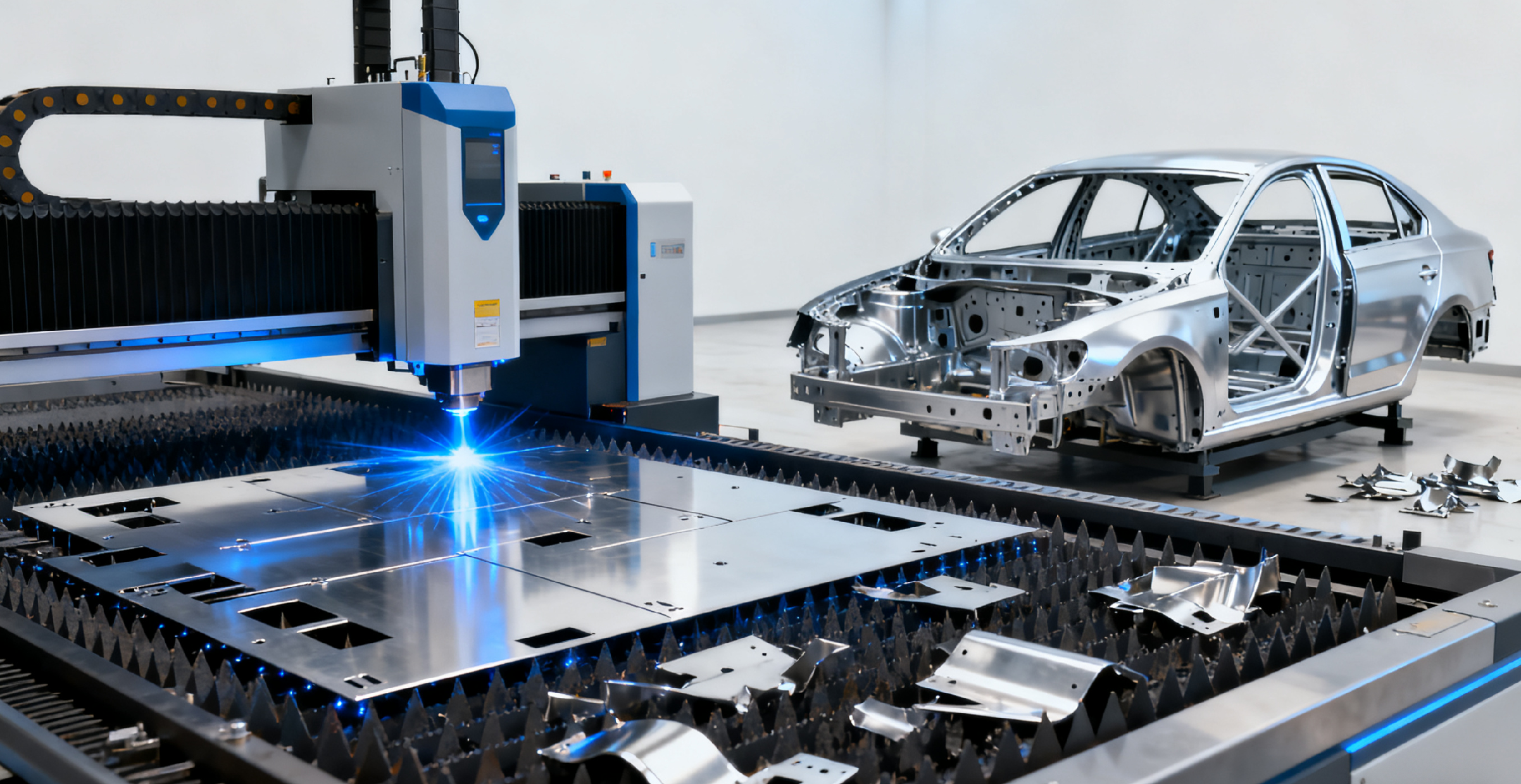

Body-in-White (BIW) Component Fabrication

The BIW, the structural framework of a vehicle, requires precise cutting of metal sheets (such as high-strength steel, aluminum alloy, and magnesium alloy) to ensure structural integrity and crash safety. Fiber laser cutting machines, with their high cutting speed and narrow kerf width (as small as 0.1mm), excel in shaping complex BIW parts like door panels, roof frames, and chassis components. For example, leading automakers like Tesla and BMW use high-power fiber laser cutters (3000W-6000W) to process high-strength steel sheets, reducing material waste by up to 15% compared to traditional stamping methods.

Powertrain and Engine Component Processing

Powertrain components—including gears, shafts, and cylinder heads—demand ultra-precise cutting to ensure smooth operation and durability. Laser cutting machines, particularly CNC-guided models, deliver micron-level accuracy, making them ideal for cutting intricate features like cooling holes, splines, and mounting slots in engine parts. Aluminum alloy, a lightweight material widely used in powertrains, is efficiently processed by fiber lasers, which minimize thermal distortion and maintain component dimensional stability.

Interior and Exterior Trim Production

From decorative stainless steel trim to lightweight plastic interior panels, laser cutting offers unmatched flexibility for automotive aesthetics. For exterior trim (e.g., grille inserts, window frames), laser cutters produce clean, burr-free edges that enhance visual appeal and reduce post-processing time. For interior components like dashboard panels and seat frames, CO₂ laser cutters (compatible with non-metallic materials) work alongside fiber lasers to create custom shapes tailored to vehicle design trends.

Battery Component Manufacturing for Electric Vehicles (EVs)

As the automotive industry shifts toward electrification, laser cutting has become indispensable in EV battery production. It is used to cut battery cell tabs (copper and aluminum foils), battery pack casings (aluminum alloy), and cooling plates with extreme precision. The non-contact nature of laser cutting prevents damage to delicate battery materials, while high-speed processing meets the mass-production demands of EV manufacturers. Companies like BYD and Volkswagen rely on laser cutting lines to achieve battery component tolerances of ±0.02mm, critical for battery safety and performance.

2. Technological Advantages That Transform Automotive Production

Laser cutting machines outperform traditional cutting methods (such as stamping, shearing, and waterjet cutting) in several key areas, making them a preferred choice for modern automakers:

Unmatched Precision: Laser cutting achieves tolerances as tight as ±0.01mm, ensuring consistent fitment of automotive components—critical for safety and assembly efficiency.

High Processing Speed: Fiber laser cutters can process 1mm-thick stainless steel at speeds up to 10m/min, significantly reducing production cycle times compared to stamping (which requires time-consuming die changes).

Material Versatility: From high-strength steel and aluminum to copper and composite materials, laser cutters handle a wide range of automotive-grade materials without tool wear.

Reduced Material Waste: Computer-aided nesting software optimizes material layout, cutting waste by 10%-20%—a key cost-saving factor for high-volume production.

Flexibility for Customization: Unlike stamping (which requires expensive dies), laser cutting can quickly switch between part designs, supporting automakers’ shift toward modular and personalized vehicle production.

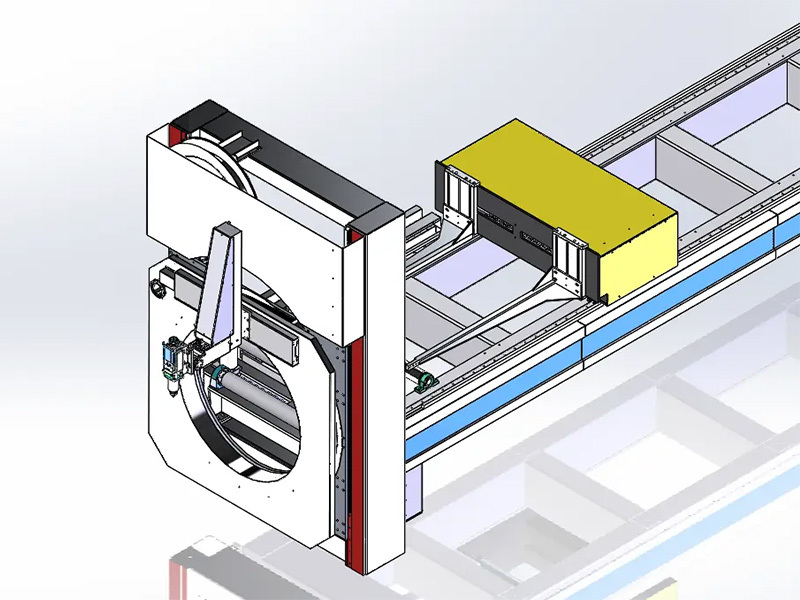

3. Case Study: How a Leading Automaker Boosted Efficiency with Laser Cutting

A European luxury automaker faced challenges with traditional stamping in producing low-volume, high-precision BIW components for its electric vehicle lineup. The company replaced three stamping presses with two 4000W fiber laser cutting machines integrated with automated loading/unloading systems. The results were striking:

Production lead time for custom components reduced by 40% (no die development or changeover time).

Material waste decreased by 18%, saving over €200,000 annually in raw material costs.

Defect rate dropped from 2.3% to 0.5% due to improved cutting precision.

This case highlights how laser cutting enables automakers to balance efficiency, quality, and flexibility—even in niche production segments.

4. Future Trends: Laser Cutting in the Next Generation of Automotive Manufacturing

As the automotive industry evolves toward electrification, lightweighting, and smart manufacturing, laser cutting technology is set to advance further:

High-Power Lasers for Thick Materials: 10kW+ fiber lasers will become more common for cutting thick aluminum and steel plates used in EV chassis and battery packs, reducing processing time by half.

Integration with Industry 4.0: Laser cutters will be connected to IoT platforms, enabling real-time monitoring of cutting parameters, predictive maintenance, and seamless integration with automated assembly lines.

Hybrid Laser Processing: Combined laser cutting and welding systems will emerge, streamlining production of complex components (e.g., EV battery modules) by reducing processing steps.

Sustainability Focus: Low-energy-consumption fiber lasers will help automakers reduce their carbon footprint, aligning with global sustainability goals.

Conclusion

Laser cutting machines have become a cornerstone of modern automotive manufacturing, driving advancements in precision, efficiency, and sustainability. From BIW production to EV battery manufacturing, their versatility and technological superiority make them indispensable for automakers aiming to stay competitive in a rapidly changing industry. As laser technology continues to evolve, it will play an even more critical role in shaping the future of mobility—enabling safer, lighter, and more innovative vehicles.

BLOGS

AChina Knoppo H Beam Cutting Machine at Sharjah STEELFAB 2025

We ask for attention of Arabian customers looking for laser cutting machines, laser welding machine , laser cleaning machine , deburring machine , H beam laser cutting machine etc, as Knoppo laser is attending a local event in UAE.

Common problems and solutions of handheld laser welding machine !

In the process of laser welding, the molten material splashes everywhere and adheres to the surface of the material, causing metal particles to appear on the surface and affecting the appearance of the product.