Why choose a visual positioning laser marking machine?

Publishing time.

Aug 16,2022

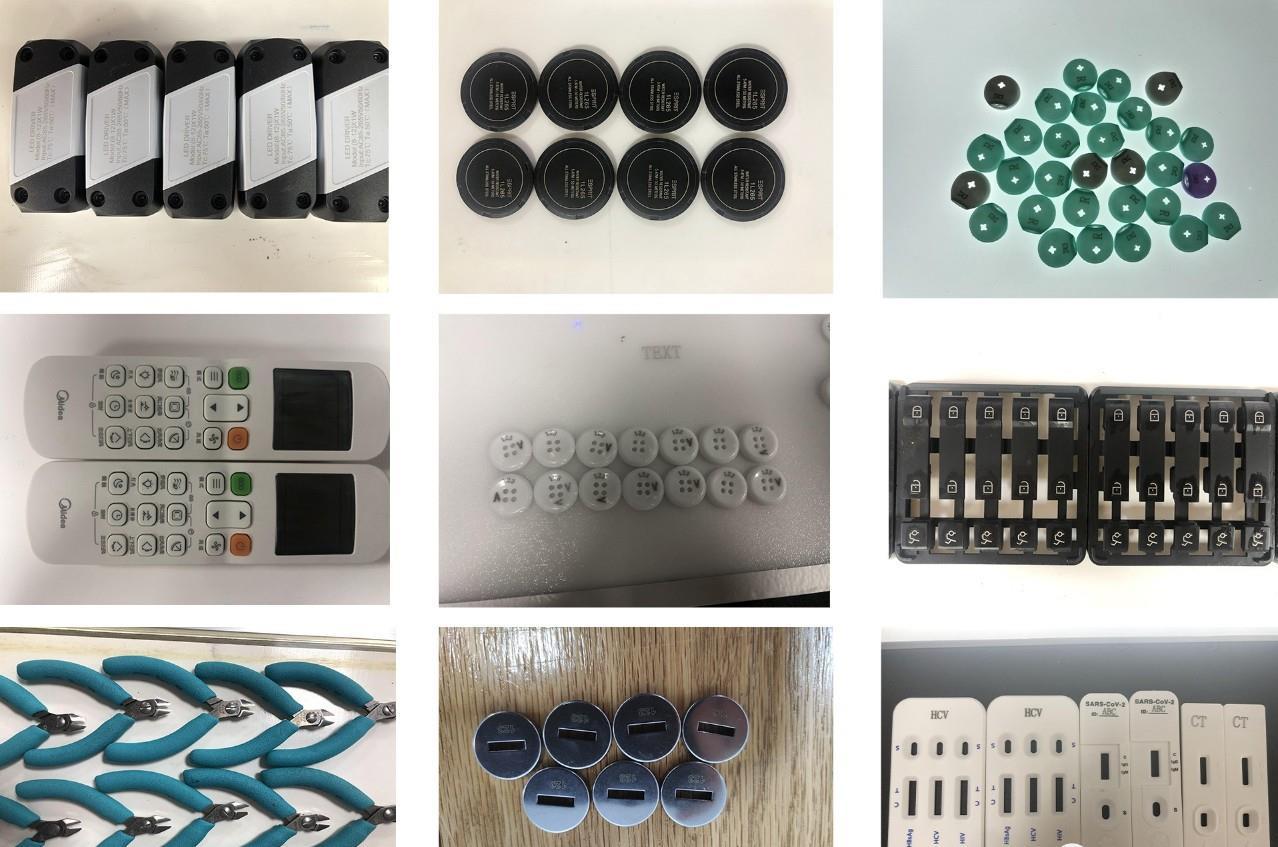

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

1. The pieces are very small, and the fixtures are manually used for positioning, which is difficult to place, slow and takes a long time;

2. There are many types of products, and many sets of fixtures are required to match, and the cost is high;

3. Manual placement requires and manual confirmation of the marking position, low efficiency and high labor cost;

4. Manual marking, there is a phenomenon that the placement is not always in same place, resulting in a high waste rate;

5. One person can only operate one machine, mass production, and the efficiency is very low;

6. There may be mistakes in manual operation, resulting in missed typing or wrong content, etc., resulting in customer complaints.

In view of the various problems encountered in the above industrial production, Knoppo visual positioning laser marking machine has its obvious advantages:

1. Need not fixtures, and it can be placed flatly at will to accurately locate;

2. Add product templates in minutes, no need to worry about the variety of products, and it is convenient to adjust the machine;

3. The marking products can be placed at will, saving customers the cost of positioning the mold and the cost of positioning time;

4. The intelligent visual positioning system automatically batch processing, and the production capacity is increased by 3 to 10 times;

5. The vision software algorithm automatically calculates the operating conditions at high speed, without human operation errors;

6. A single person can operate multiple devices at the same time, greatly improving the efficiency;

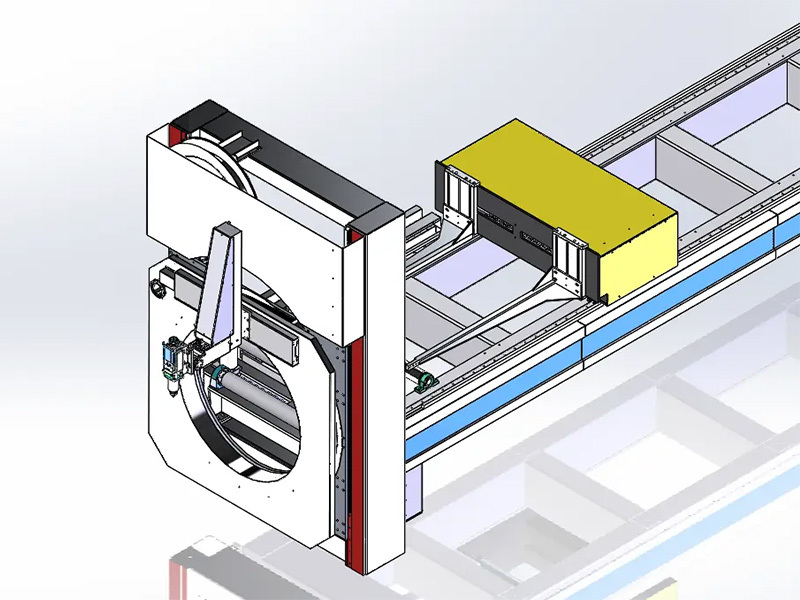

7. It can be matched with mechanical platforms such as assembly line, X/Y platform, and multi-station to realize automatic laser marking;

BLOGS

AChina Knoppo H Beam Cutting Machine at Sharjah STEELFAB 2025

We ask for attention of Arabian customers looking for laser cutting machines, laser welding machine , laser cleaning machine , deburring machine , H beam laser cutting machine etc, as Knoppo laser is attending a local event in UAE.

Common problems and solutions of handheld laser welding machine !

In the process of laser welding, the molten material splashes everywhere and adheres to the surface of the material, causing metal particles to appear on the surface and affecting the appearance of the product.

Why choose a visual positioning laser marking machine?

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

Knoppo H Beam Plasma Cutting Machine Exported To Turkey !

Knoppo T400 H beam CNC cutting machines are a good helper for steel fabricators , not just for cutting H beam or pipes very efficiently, but also for drawing , beveling and much more. Japan Fuji servo motor and driver , Shanghai Fangling control system and America Hypertherm plasma souce , good quality and 3 years warranty , this machine have help Knoppo customer get big project , very efficiently .

Knoppo Laser Cleaning Machine , Meet A Variety Of Metal Cleaning Requirements

Recently , with the increased of awareness of environmental protection , that provided new development opportunities for many industries in the metal cleaning field. laser cleaning as a new type of environmentally friendly cleaning technology has huge market potential.

KNOPPO Fiber Laser Beveling Cutting Machine , Solve Thick Steel Welding Problems !

In some heavy metal processing industries, such as the shipbuilding industry, mining machinery, and construction machinery, such problems are often encountered: how to achieve solid welding of metal parts and metal parts?