Knoppo H Beam Plasma Cutting Machine Exported To Turkey !

Publishing time.

Aug 05,2022

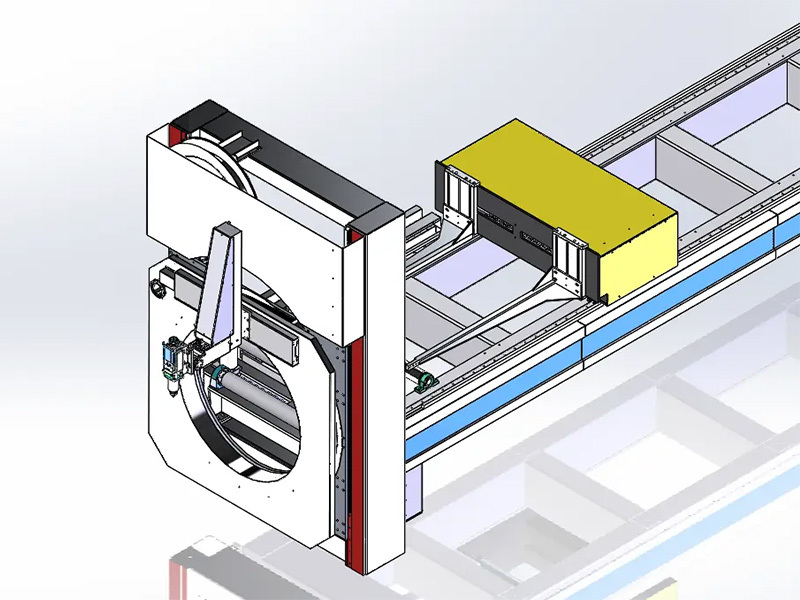

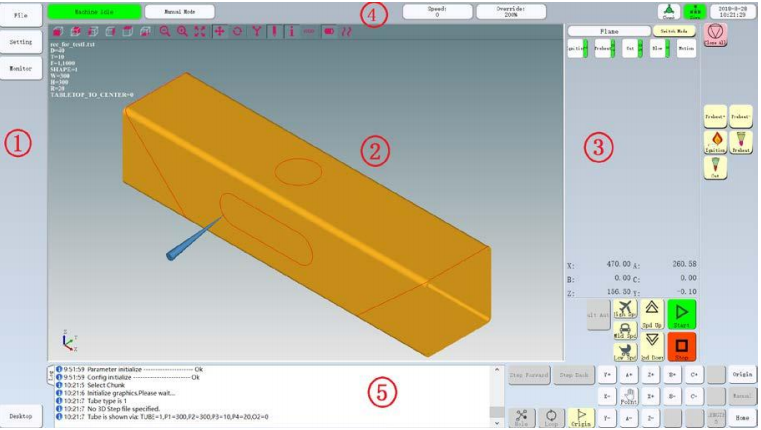

Knoppo T400 H beam CNC cutting machines are a good helper for steel fabricators , not just for cutting H beam or pipes very efficiently, but also for drawing , beveling and much more. Japan Fuji servo motor and driver , Shanghai Fangling control system and America Hypertherm plasma souce , good quality and 3 years warranty , this machine have help Knoppo customer get big project , very efficiently .

Knoppo T400 H beam CNC cutting machines are a good helper for steel fabricators , not just for cutting H beam or pipes very efficiently, but also for drawing , beveling and much more. Japan Fuji servo motor and driver , Shanghai Fangling control system and America Hypertherm plasma souce , good quality and 3 years warranty , this machine have help Knoppo customer get big project , very efficiently . our pipe plasma cutting machine were exported to Vietnam , USA , Austrilia , Europe , Russia and India etc . Recently , T400 H beam cutting machine was exported to Turkey successfully .

T400 H beam cutting machine is a complete solution for designing, drawing , CNC plasma cutting and beveling of round section , H beams , Tube, RHS, Angle & Channel etc , that is built for higher-volume work , And ideal for manufacturers and serious fabricators.

With Knoppo ‘ precision cutting, you can use T400 H beam cutting machine for a wide range of applications in facilities and industries where accuracy is essential, such as fabrication shops, steel enginering , rails and motorsport, and construction .

Knoppo is a CNC cutting solutions supplier for metal cutting , such as , metal sheet , metal pipe , RHS etc , cutting diameter and length can be customized . Beveling can be option .

|

Model |

T300 |

T400 | RT400 |

|

Max Cutting Diameter |

400 mm |

800 mm | 1200 mm |

|

Cutting Length |

6m / 12m |

||

|

Number of Cutting Tool |

1 Gas Cutting Torch or 1 Plasma Cutting Torch |

||

|

Capacity |

Gas: 150mm; Plasma: depends |

||

|

Transmission |

AC Servo Motor, 6 Axis Control |

||

|

Positioning Accuracy |

0.1 mm |

||

|

Feeding Type |

Automatic Feeding System with Rail |

||

|

Unloading |

Roller Supports |

||

|

Drawing |

Tubemaster |

||

For more details , please contact with us by E-mail or whatsapp .

max@knoppoauto.com

BLOGS

AChina Knoppo H Beam Cutting Machine at Sharjah STEELFAB 2025

We ask for attention of Arabian customers looking for laser cutting machines, laser welding machine , laser cleaning machine , deburring machine , H beam laser cutting machine etc, as Knoppo laser is attending a local event in UAE.

Common problems and solutions of handheld laser welding machine !

In the process of laser welding, the molten material splashes everywhere and adheres to the surface of the material, causing metal particles to appear on the surface and affecting the appearance of the product.

Why choose a visual positioning laser marking machine?

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

Knoppo H Beam Plasma Cutting Machine Exported To Turkey !

Knoppo T400 H beam CNC cutting machines are a good helper for steel fabricators , not just for cutting H beam or pipes very efficiently, but also for drawing , beveling and much more. Japan Fuji servo motor and driver , Shanghai Fangling control system and America Hypertherm plasma souce , good quality and 3 years warranty , this machine have help Knoppo customer get big project , very efficiently .

Knoppo Laser Cleaning Machine , Meet A Variety Of Metal Cleaning Requirements

Recently , with the increased of awareness of environmental protection , that provided new development opportunities for many industries in the metal cleaning field. laser cleaning as a new type of environmentally friendly cleaning technology has huge market potential.

KNOPPO Fiber Laser Beveling Cutting Machine , Solve Thick Steel Welding Problems !

In some heavy metal processing industries, such as the shipbuilding industry, mining machinery, and construction machinery, such problems are often encountered: how to achieve solid welding of metal parts and metal parts?