Knoppo Laser Cleaning Machine , Meet A Variety Of Metal Cleaning Requirements

Publishing time.

Jul 19,2022

Recently , with the increased of awareness of environmental protection , that provided new development opportunities for many industries in the metal cleaning field. laser cleaning as a new type of environmentally friendly cleaning technology has huge market potential.

Recently , with the increased of awareness of environmental protection , that provided new development opportunities for many industries in the metal cleaning field. laser cleaning as a new type of environmentally friendly cleaning technology has huge market potential.

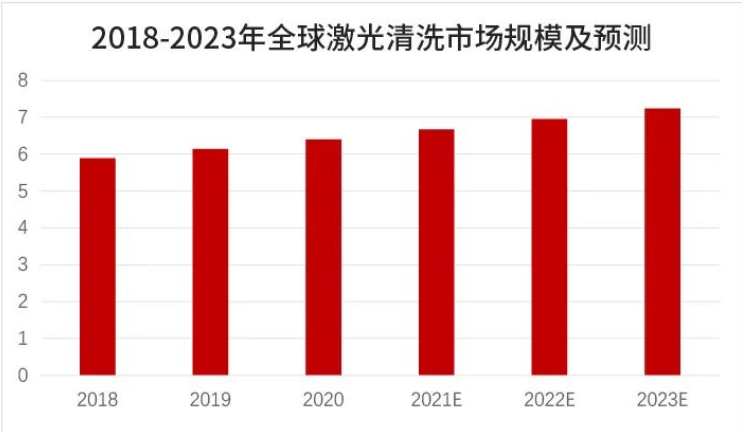

According to the statistics of the Prospective Research Institute, the global laser cleaning market has grown year by year in recent years, and it is expected to exceed US$800 million by 2023. With the increase of the laser cleaning market, laser machine manufacturers have also ushered in vigorous development.

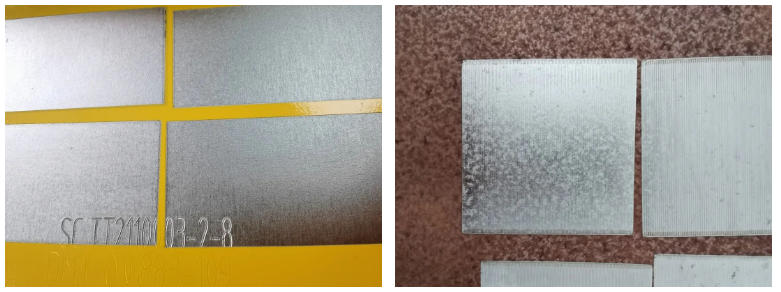

Traditional cleaning methods: mainly mechanical cleaning and chemical cleaning, etc. Mechanical cleaning is a contact cleaning, which will generate stress and damage the substrate; chemical cleaning will corrode the surface of the workpiece, and the pollution is harmful to the human body.Principle of laser cleaning: Using a high power density laser to act on the surface of the workpiece to be cleaned (non-contact), the pollutants on the surface of the workpiece absorb the focused laser energy and rapidly expand, vaporize, and peel off, thereby separating from the surface of the workpiece to achieve the purpose of cleaning.

Therefore, laser cleaning machine has the advantages of high efficiency, non-contact, no damage, green environmental protection, low cost, flexible control, etc. Compared with traditional cleaning methods, laser cleaning technology occupies an absolute advantage.

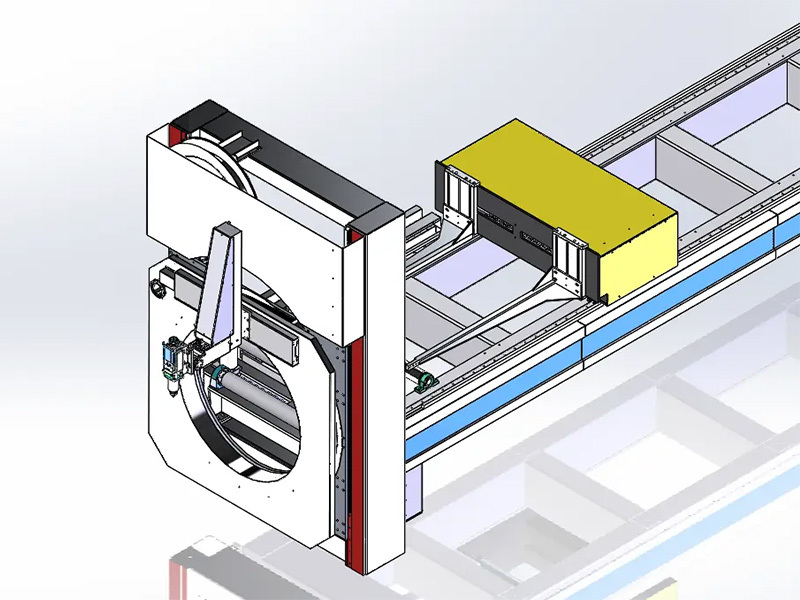

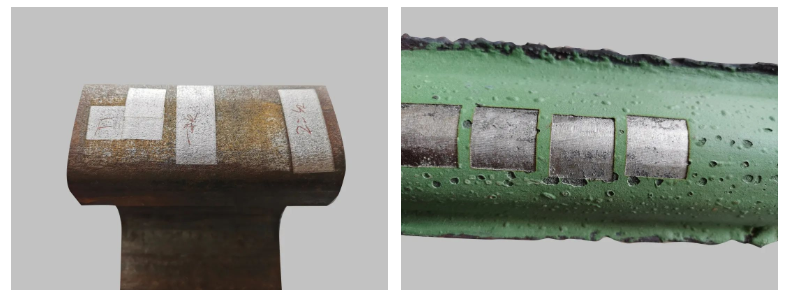

Knoppo laser is a laser company aiming to become an advanced laser machine supplier for precision manufacturing. In the field of laser cleaning, it can provide 100w~1000W pulsed laser cleaning machine and 1000w ~3000w continious laser cleaning machine with strong cleaning ability, compact air-cooled structure, and easy portability; high cleaning efficiency, no damage to the substrate. Knoppo laser cleaning machine can be used for metal surface paint removal, rust removal, precision mold cleaning, cultural relics protection, high-end machine tools, track maintenance, etc. It is widely used in the industry and meets the cleaning requirements of different substrates.

In the future, with the increasing demand for laser cleaning, higher requirements will also be placed on the process of laser cleaning technology. Knoppo laser will continue to make efforts in the field of laser cleaning. Through independent innovation, it will update and iterate products, and continue to upgrade to provide customers with more cleaning options.

BLOGS

AChina Knoppo H Beam Cutting Machine at Sharjah STEELFAB 2025

We ask for attention of Arabian customers looking for laser cutting machines, laser welding machine , laser cleaning machine , deburring machine , H beam laser cutting machine etc, as Knoppo laser is attending a local event in UAE.

Common problems and solutions of handheld laser welding machine !

In the process of laser welding, the molten material splashes everywhere and adheres to the surface of the material, causing metal particles to appear on the surface and affecting the appearance of the product.

Why choose a visual positioning laser marking machine?

Why do we choose Knoppo visual positioning laser marking machine? At present, the production will have the following problems:

Knoppo H Beam Plasma Cutting Machine Exported To Turkey !

Knoppo T400 H beam CNC cutting machines are a good helper for steel fabricators , not just for cutting H beam or pipes very efficiently, but also for drawing , beveling and much more. Japan Fuji servo motor and driver , Shanghai Fangling control system and America Hypertherm plasma souce , good quality and 3 years warranty , this machine have help Knoppo customer get big project , very efficiently .

Knoppo Laser Cleaning Machine , Meet A Variety Of Metal Cleaning Requirements

Recently , with the increased of awareness of environmental protection , that provided new development opportunities for many industries in the metal cleaning field. laser cleaning as a new type of environmentally friendly cleaning technology has huge market potential.

KNOPPO Fiber Laser Beveling Cutting Machine , Solve Thick Steel Welding Problems !

In some heavy metal processing industries, such as the shipbuilding industry, mining machinery, and construction machinery, such problems are often encountered: how to achieve solid welding of metal parts and metal parts?