CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

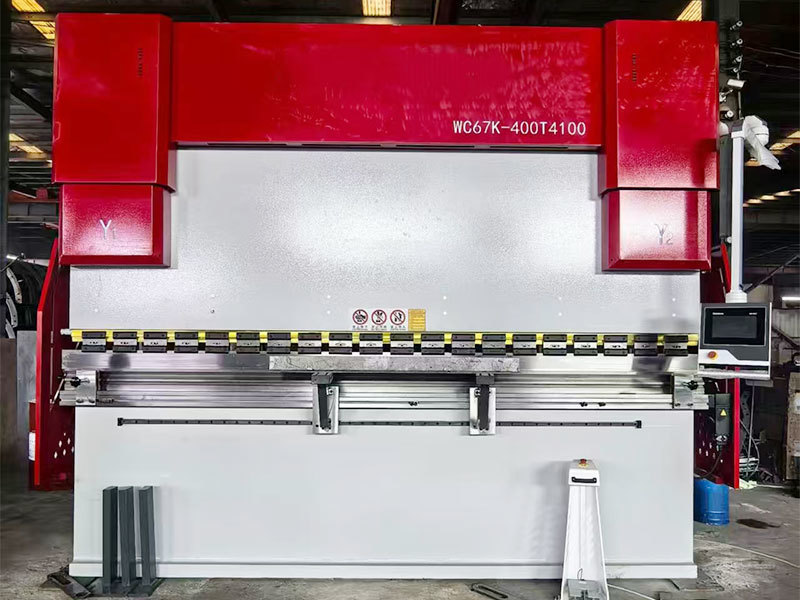

CNC Press Brake

1.Electrical system 1)The machine adopts 380V, three-phase four-wire power supply. 2)Electrical components and materials are in line with national standards. 3)The main circuit of the motor is provided with short circuit, overload and phase loss protection.

Keywords:

Bending Machine

Technical Parameters

|

Serial number |

Parameter Name |

Parameter |

Unit |

Remark |

|

|

1 |

Nominal Pressure |

4000 |

KN |

|

|

|

2 |

Worktable length |

4000 |

mm |

|

|

|

3 |

Column spacing |

5000 |

mm |

|

|

|

4 |

Throat Depth |

405 |

mm |

|

|

|

5 |

Maximum open height between table and slider |

560 |

mm |

|

|

|

6 |

Slide Stroke |

300 |

mm |

|

|

|

7 |

Number of CNC axis |

8+1 Mechanical crowning |

|||

|

8 |

Main servo motor |

2 no. 17 kw |

|||

|

9 |

Speed of slide |

No load |

150 |

mm/s |

|

|

Work |

13 |

mm/s |

|

||

|

Return |

150 |

mm/s |

|

||

|

10 |

Machine Dimensions |

Length |

4360 |

mm |

|

|

Width |

2100 |

mm |

|

||

|

Height |

3200 |

mm |

|

||

CONFIGURATION

|

Serial number |

Name |

The manufacturer |

Notes |

|

1 |

Numerical control system |

DA-69T |

|

|

2 |

The hydraulic system |

Germany AGRO |

|

|

3 |

Electrical appliances |

Schneider |

|

|

4 |

Crowning |

Mechanical Type |

|

|

5 |

Main motor |

Weichuang |

|

|

6 |

Oil pump |

Sunny/First America |

|

|

7 |

Ball screw, linear guide rail |

Taiwan TBI |

|

|

8 |

Sealing ring |

SKF Italy |

|

|

9 |

Servo motor |

KAIZ |

|

|

10 |

Grating ruler |

OPK |

Main structure of equipment

1.Electrical system

1)The machine adopts 380V, three-phase four-wire power supply.

2)Electrical components and materials are in line with national standards.

3)The main circuit of the motor is provided with short circuit, overload and phase loss protection.

(Electrical wiring diagram-reference)

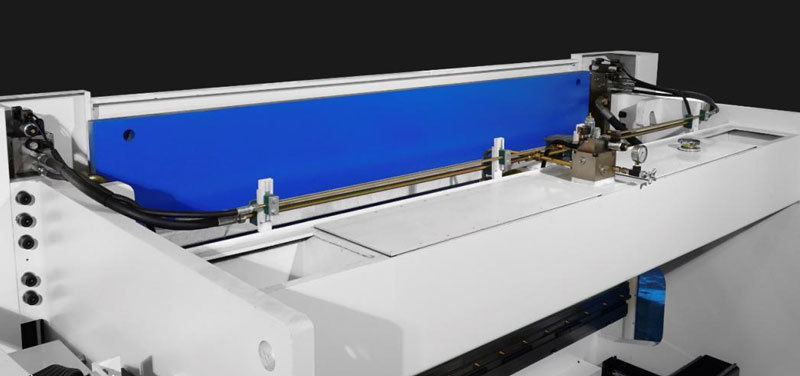

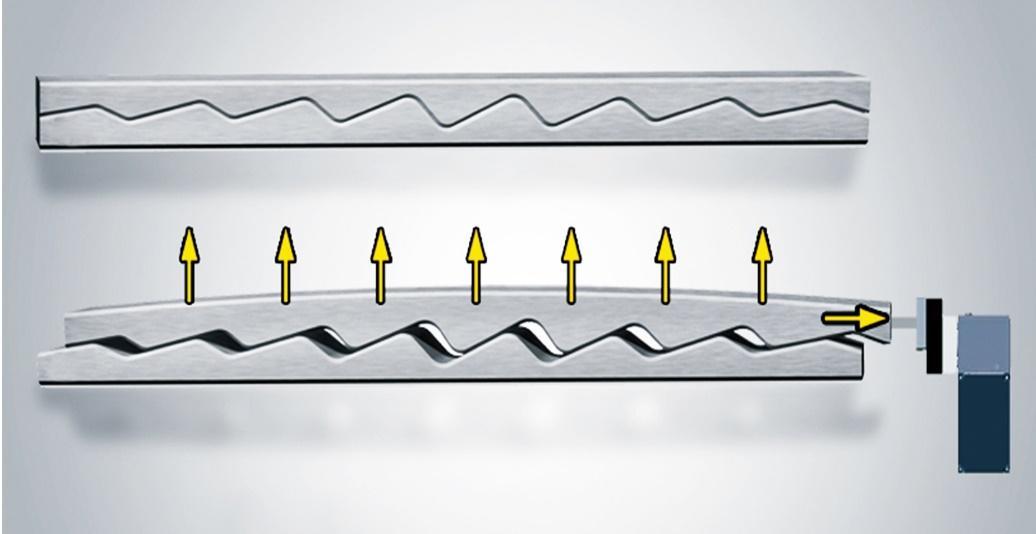

2.Hydraulic system,synchronization technology and crowning technology

|

1) Hydraulic system The German AGRO company proportional servo valve drive can guarantee extremely high synchronization control precision. The integrated hydraulic control system simplifies the pipeline, prevents leakage, improves the stability of the machine tool, and also makes the appearance more simple and beautiful. The internal gear pump ensures low noise and long service life of the whole system. |

|

2) Synchronization technology The position of the slider is fed back to the NUMERICAL control system by the grating ruler on both sides. Then the controller controls the size of the opening and the amount of oil in the cylinder, so as to control the synchronous operation of the slider(Y1,Y2) and keep the parallel state of the working table. The controller automatically controls the deflection compensation of the worktable according to the state of the machine, so as to achieve the uniform and consistent effect of the full-length Angle of the work piece. |

|

3) Crowning technology The automatic crowning system overcomes the influence of the sliding block deformation on the work piece quality in the working process and ensures the good straightness and bending Angle of the work piece. |

3.Structure of the machine

1)Rack

Beautiful appearance design.

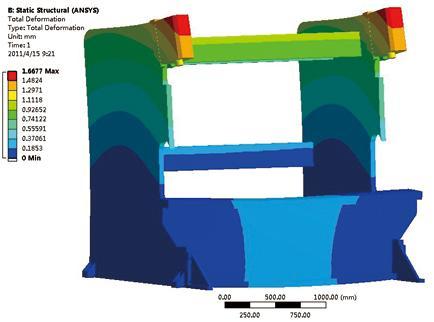

The world famous finite element software ANSYS is used for the finite element analysis and optimization design of the main components.

The machine is made of sheet plate welded structure with good rigidity.

Natural aging and vibration to eliminate internal stress.

The structural parts are spayed with anti-rust paint.

The vertical column of the machine tool and the lower table are processed by large milling machine in one time, which insure the parallelism and perpendicularity of each mounting surface.

The bending Angle accuracy can reach±30ˊ.

|

|

2)The slider

The slide is made of whole steel plate and is fixed with two oil cylinders by connecting shaft.

3)Beam, linear guide,ball screw

High quality beam and famous brand linear guide & ball screw (TBI).

|

|

Equipment quality standard and machine implementation standard

1.Equipment quality standard

The designs and manufacture in accordance with the professional standards of the People's Republic of China. The operation of the quality system strictly follow the "quality manual", "procedure document", "work instruction" and all kinds of relevant technical standards and management standards. All employees comply with and implement the company's quality policy, namely: "adhere to scientific management, strict process control, to provide customers with quality products and satisfactory services".

|

|

|

2.Machine implementation standard

JB/T1829-1997 General technical conditions for forging and pressing machines

GB/T7120-1997 Mechanical safety and technical conditions

GB/T3766-2001 General technical conditions of hydraulic system

JB/T5994-1992 General technical conditions for assembly

GB/T5226.1-1996 General technical conditional for industrial machinery and electrical equipment

JB/T5946-1991 General technical conditions for coating

GB16754-1997 Mechanical safety emergency stop design principle

GB/T17120-1997 Safety technical conditions of forging press machinery

3.Installation and debugging, technical support and after-sales service

1)The warranty period of the whole machine will be 12 months (except for wearing parts).The warranty period is calculated from the date of delivery.

2)In case of any components failure during the warranty period, we are ready to provide telephone and/or online support. If necessary, our technicians are ready to go to your side in case of the equipment malfunctions, the customer should bear the cost of the engineer(air tickets, transportation & accommodation)

3) During warranty period, we will deliver the parts for free(including the expenses of parts and transportation) if the parts cannot work due to Non-human reasons.

4.If any part need to be repaired in China, the transportation fees from the customer’s factory to china and the customs clearance fees in China sea port should be borne by the customer, the transportation fees from China to customer’s factory should be borne by the supplier.

5.Service after the warranty period: we provide continuous services and support for our customers when the warranty period is expired, the customer should bear the expenses of air tickets, parts cost, accommodation and engineer cost(100usd/day/person).

The buyer needs to prepare the following in advance

1)The foundation of machine shall be prepared according to drawings from the supplier.

2)When the machine arrives at the site, the buyer should cooperate with the seller to provide the corresponding lifting equipment, hydraulic oil, electricity and other necessary conditions and parts.

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

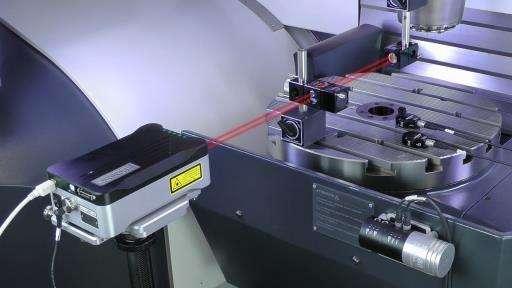

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine