CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

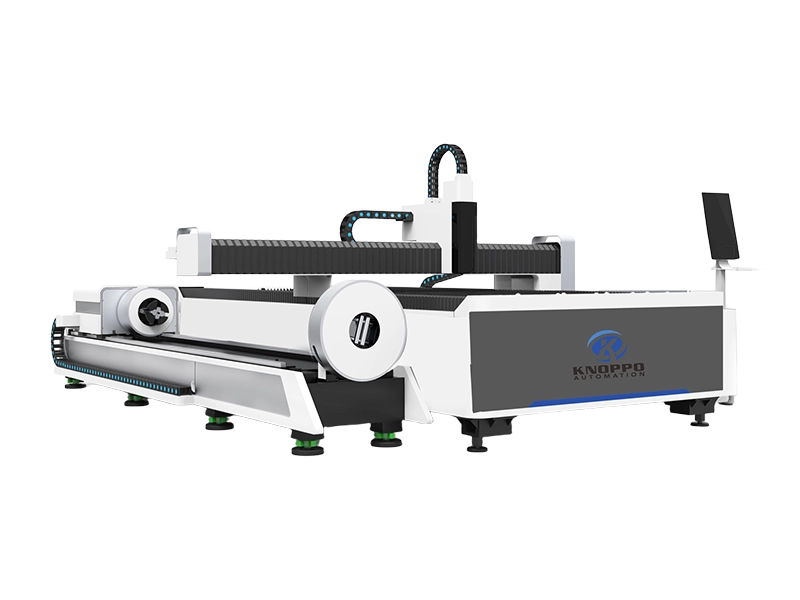

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

Keywords:

Fiber Laser Cutting Machine

|

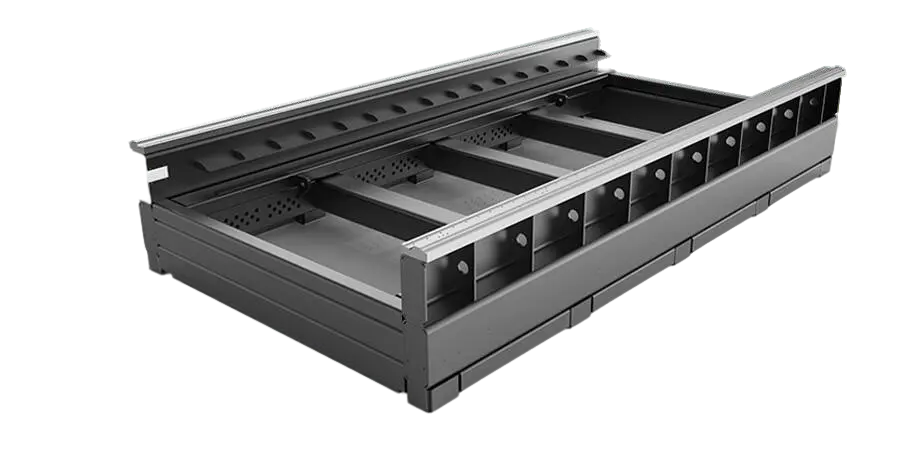

Strong Machine Body: Made of flake graphite cast iron with a minimum tensile strength of 200MPa, high carbon content, high compressive strength, and hardness. It has strong shock absorption and wear resistance, low thermal sensitivity and bed gap sensitivity, ensuring long-term precision retention without deformation throughout its service life. |

|

BLT Laser Head: Applicable to various focal lengths, with the focal point automatically adjusted by the machine tool control system to adapt to different thicknesses of sheets. It adopts Switzerland Lightning technology, featuring short piercing time (saving 90% of piercing time), unaffected by material quality, excellent cutting sections, and saving gas and electricity costs. Equipped with built-in double water-cooling structures to extend lens life and multiple protective lenses. |

|

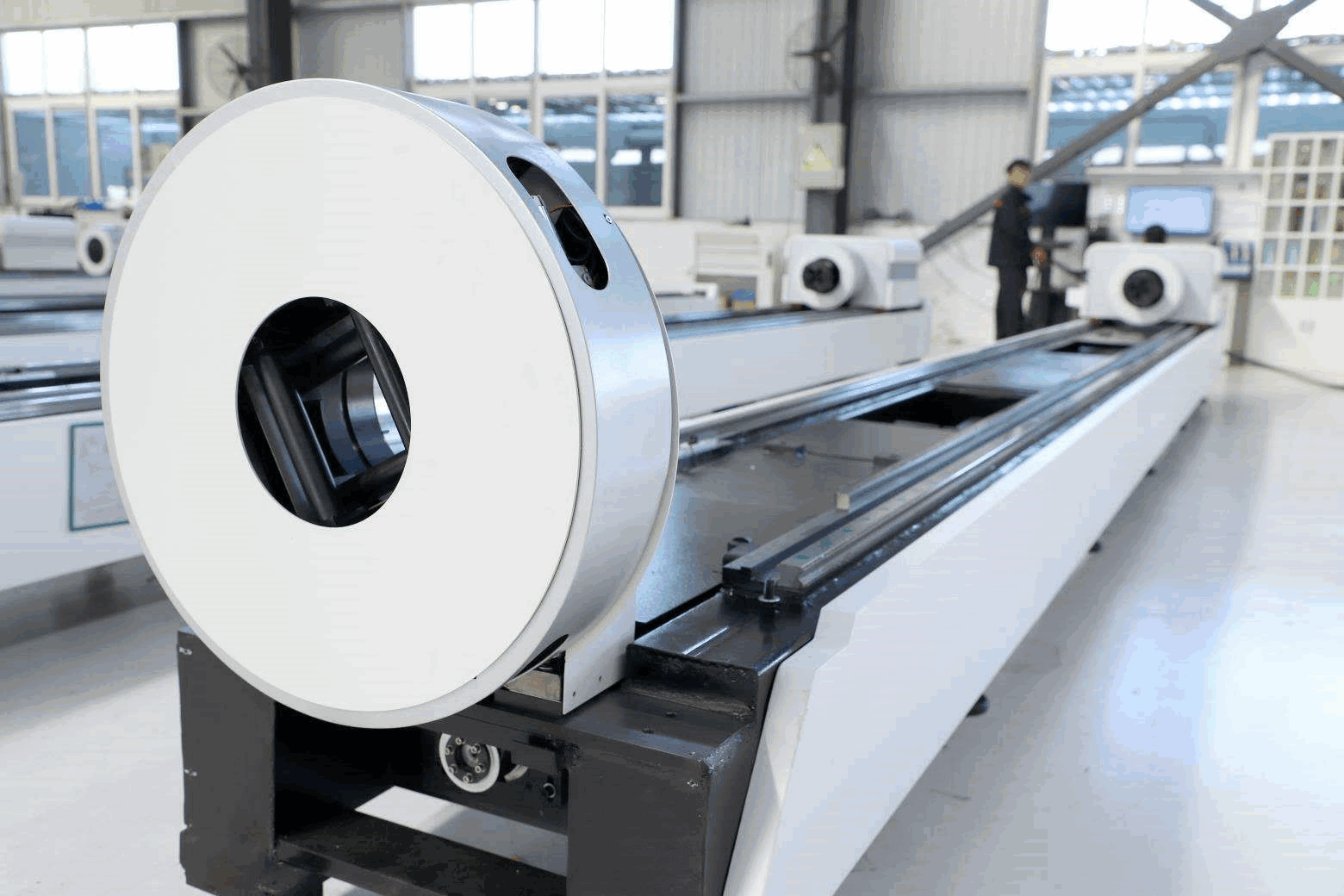

Self-Centering Chuck: Automatic electric chuck driven by a claw DC motor, with sensitive, adjustable, and stable clamping current. It has a wide clamping range and large clamping force, enabling non-destructive pipe clamping, fast automatic centering and clamping, stable performance, high transmission efficiency, and long service life. |

|

Multiple Intelligent Functions: Including auxiliary feeding mechanism (reducing friction for convenient loading/unloading), intelligent travel protection (monitoring operation range to ensure safety), automatic lubrication system (providing timing and quantitative oil supply with alarm functions), WIFI remote intelligent assistance (real-time feedback and fault diagnosis), a new generation of safety following module (avoiding collisions), intelligent alarm system (pushing abnormal information), and auxiliary gas low pressure alarm (real-time pressure detection). |

Parameters

|

Model |

KF-TSeries |

|

Sheet Cutting Area |

3000*1500mm / 6000*1500mm / 6000*2000mm/ 6000*2500mm |

|

Tube Cutting Length |

3m / 6m |

|

Laser Power |

1500W / 2000W / 3000W / 6000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Introduction:

KF3015T IPG high speed CNC sheet metal pipe tube fiber laser cutting machine is mainly used for metal pipe and sheet cutting . 1KW ~ 8KW is available , 3 years warranty .

CNC Sheet Metal And Tube Fiber Laser Cutting Machine KF3015T

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

STRONG MACHINE BODY

Using flake graphite cast iron, the lowest tensile strength of which is 200MPa. High carbon content, high compressive strength and high hardness. Strong shock absorption and wear resistance. Low thermal sensitivity and bed gap sensitivity reduce the loss of equipment in using, so the machine accuracy could maintain fora long time, and no deformation in a life cycle.

AUTO-FOCUS

Applicable to various focal lengths, which are controlled by machine tool control system. Focal point will be automatically adjusted in cutting process to achieve the best cutting effect of different thicknesses sheets metal.

Free

Free your hands. Focal length is controlled by operating system. We don't need to do manual regulation,which effectively avoids errors or faults caused by manual operation.

Fast

Adopt Switzerland Lightning technology, perforation time is short, 90% of perforation time is saved; Switzerland Lightning combined with Raytools improved new process so that the perforation is not affected by the material quality and achieve perfect cutting with the best cutting section; saving cutting gas and electricity, saving cost.

When replacing different materials or different thicknesses sheet, manual focus laser head needs to adjust focal length manually,very inefficient; auto focus laser head can read system storage parameters automatically, very efficient.

Accuracy

Increasing perforation focus length, separately setting perforation focal length and cutting focal length,enhance cutting accuracy.

Durable

Built-in double water-cooling structures can ensure constant temperature of collimating and focusing components,avoid lenses overheating and extend service life of lenses; Increasing collimation protective lens and focus protective lens, carefully protect key components.

Automatic electric chuck, claw DC motor drive, clamping motor current is sensitive, adjustable and stable, clamping range is wider and clamping force is larger. Non - destructive pipe clamping, fast automatic centering and clamping pipe, performance is more stable. The chuck size is smaller, rotation inertia is low, and dynamic performance is strong. Self-centering electric chuck, gear transmission mode, higher transmission efficiency, long working life and high work reliability.

FUNCTIONS OF KF3015T MODEL

Auxiliary feeding mechanism:The promotion and demotion of subsidiary roller table reduces friction force between parts and working table, making loading and unloading more convenient.

Intelligent travel protection:Automatically monitor operation range of crossbeam and cutting parts, keeping operation within machining range. Double guarantees of fixed limitation greatly improve equipment and personal safety, minimizing the using risks.

Automatic lubrication system:Automatic lubrication system provides timing and ration lubricating oil for equipment to ensure its normal and high speed operation, and owns functions of abnormal alarm and liquid level alarm. The system greatly enhances cutting accuracy and effectively extends service life of transmission mechanism!

WIFI remote intelligent assistance:Global real-time feedback ; Providing real-time fault analysis and troubleshooting.

A new generation of safety following module:Laser head keeping distance with work piece in cutting process can reduce collision risks. It will stop cutting when colliding plate. The safety following module reduces accident rate and improves cutting performance.

Intelligent alarm system:The system will start full abnormal alarm and push it to the interface through control center when equipment is abnormal. Finding equipment abnormal in advance and reducing hidden dangers can multiply improve the equipment troubleshooting efficiency.

Auxiliary gas low pressure alarm function:Providing real-time pressure detection, pushing abnormal information when pressure value is lower than optimal cutting effect and precision. Ensure the cutting performance, accuracy and timeliness of gas replacemet.

Cutting Parameters

| Cutting Parameters | 1000W | 1500W | 2000W | 3000W | 6000W | |

| Material | Thickness | speed m/min | speed m/min | speed m/min | speed m/min | speed m/min |

| Carbon steel | 1 | 8.0--10 | 15--26 | 24--32 | 30--40 | 33--43 |

| 2 | 4.0--6.5 | 4.5--6.5 | 4.7--6.5 | 4.8--7.5 | 15--25 | |

| 3 | 2.4--3.0 | 2.6--4.0 | 3.0--4.8 | 3.3--5.0 | 7.0--12 | |

| 4 | 2.0--2.4 | 2.5--3.0 | 2.8--3.5 | 3.0--4.2 | 3.0--4.0 | |

| 5 | 1.5--2.0 | 2.0--2.5 | 2.2--3.0 | 2.6--3.5 | 2.7--3.6 | |

| 6 | 1.4--1.6 | 1.6--2.2 | 1.8--2.6 | 2.3--3.2 | 2.5--3.4 | |

| 8 | 0.8--1.2 | 1.0--1.4 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | |

| 10 | 0.6--1.0 | 0.8--1.1 | 1.1--1.3 | 1.2--2.0 | 1.5--2.4 | |

| 12 | 0.5--0.8 | 0.7--1.0 | 0.9--1.2 | 1.0--1.6 | 1.2--1.8 | |

| 14 | 0.5--0.7 | 0.8--1.0 | 0.9--1.4 | 0.9--1.2 | ||

| 16 | 0.6-0.8 | 0.7--1.0 | 0.8--1.0 | |||

| 18 | 0.5--0.7 | 0.6--0.8 | 0.6--0.9 | |||

| 20 | 0.5--0.8 | 0.5--0.8 | ||||

| 22 | 0.3--0.7 | 0.4--0.8 | ||||

| Stainless steel | 1 | 18--25 | 20--27 | 24--50 | 30--35 | 32--45 |

| 2 | 5--7.5 | 8.0--12 | 9.0--15 | 13--21 | 16--28 | |

| 3 | 1.8--2.5 | 3.0--5.0 | 4.8--7.5 | 6.0--10 | 7.0--15 | |

| 4 | 1.2--1.3 | 1.5--2.4 | 3.2--4.5 | 4.0--6.0 | 5.0--8.0 | |

| 5 | 0.6--0.7 | 0.7--1.3 | 2.0-2.8 | 3.0--5.0 | 3.5--5.0 | |

| 6 | 0.7--1.0 | 1.2-2.0 | 2.0--4.0 | 2.5--4.5 | ||

| 8 | 0.7-1.0 | 1.5--2.0 | 1.2--2.0 | |||

| 10 | 0.6--0.8 | 0.8--1.2 | ||||

| 12 | 0.4--0.6 | 0.5--0.8 | ||||

| 14 | 0.4--0.6 | |||||

| Aluminum | 1 | 6.0--10 | 10--20 | 20--30 | 25--38 | 35--45 |

| 2 | 2.8--3.6 | 5.0--7.0 | 10--15 | 10--18 | 13--24 | |

| 3 | 0.7--1.5 | 2.0--4.0 | 5.0--7.0 | 6.5--8.0 | 7.0--13 | |

| 4 | 1.0--1.5 | 3.5--5.0 | 3.5--5.0 | 4.0--5.5 | ||

| 5 | 0.7--1.0 | 1.8--2.5 | 2.5--3.5 | 3.0--4.5 | ||

| 6 | 1.0--1.5 | 1.5--2.5 | 2.0--3.5 | |||

| 8 | 0.6--0.8 | 0.7--1.0 | 0.9--1.6 | |||

| 10 | 0.4--0.7 | 0.6--1.2 | ||||

| 12 | 0.3-0.45 | 0.4--0.6 | ||||

| 16 | 0.3--0.4 | |||||

| Brass | 1 | 6.0--10 | 8.0--13 | 12--18 | 20--35 | 25--35 |

| 2 | 2.8--3.6 | 3.0--4.5 | 6.0--8.5 | 6.0--10 | 8.0--12 | |

| 3 | 0.5--1.0 | 1.5--2.5 | 2.5--4.0 | 4.0--6.0 | 5.0--8.0 | |

| 4 | 1.0--1.6 | 1.5--2.0 | 3.0-5.0 | 3.2--5.5 | ||

| 5 | 0.5--0.7 | 0.9--1.2 | 1.5--2.0 | 2.0--3.0 | ||

| 6 | 0.4--0.9 | 1.0--1.8 | 1.4--2.0 | |||

| 8 | 0.5--0.7 | 0.7--1.2 | ||||

| 10 | 0.2--0.5 | |||||

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine