CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

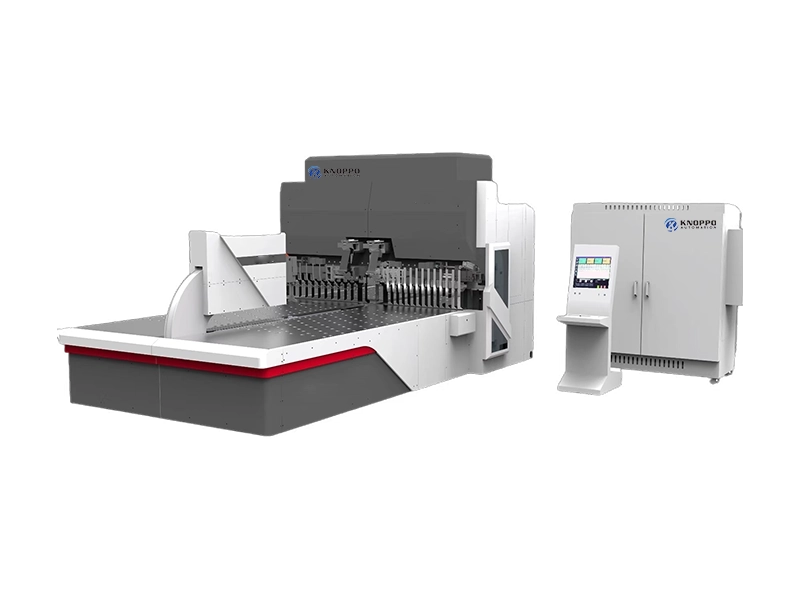

CNC Panel Bender

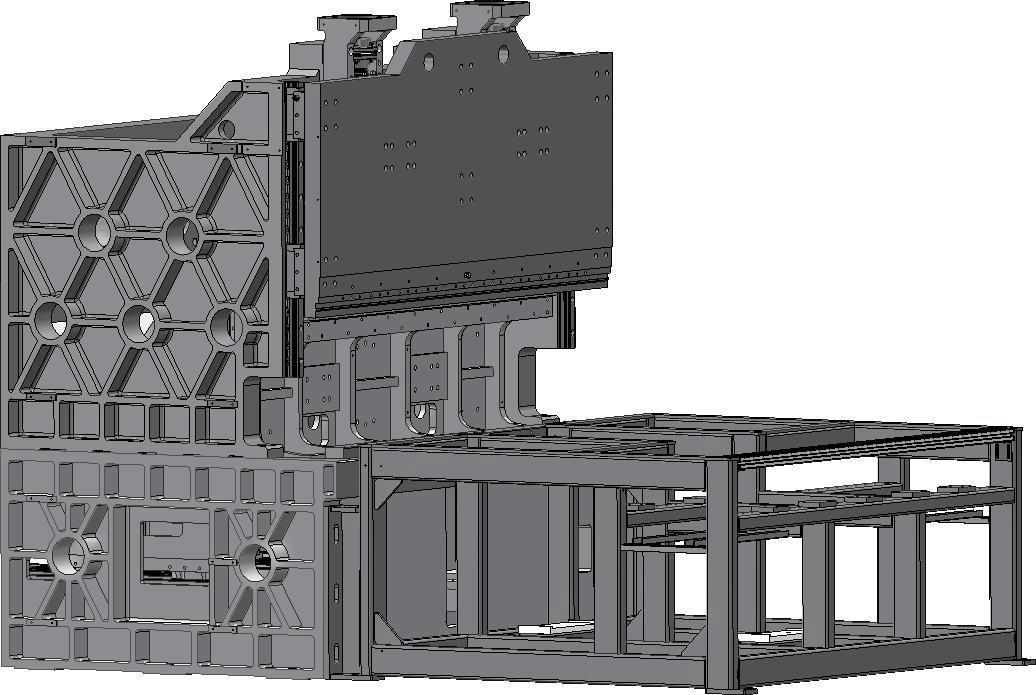

The AG/AGP series is a flexible and intelligent panel bender designed and produced according to high-precision machine tool standards. It is made of high-specification castings, and both the cast and welded parts are subjected to strict stress relief processing. High-precision machine tools are used for integrated processing, ensuring long- term accuracy, stability, and high rigidity during operation.

Keywords:

Bending Machine

TECHNICAL PROPOSAL

(i)Main Performance Characteristics

|

1. Machine Performance The AG/AGP series is a flexible and intelligent panel bender designed and produced according to high-precision machine tool standards. It is made of high-specification castings, and both the cast and welded parts are subjected to strict stress relief processing. High-precision machine tools are used for integrated processing, ensuring long- term accuracy, stability, and high rigidity during operation. |

|

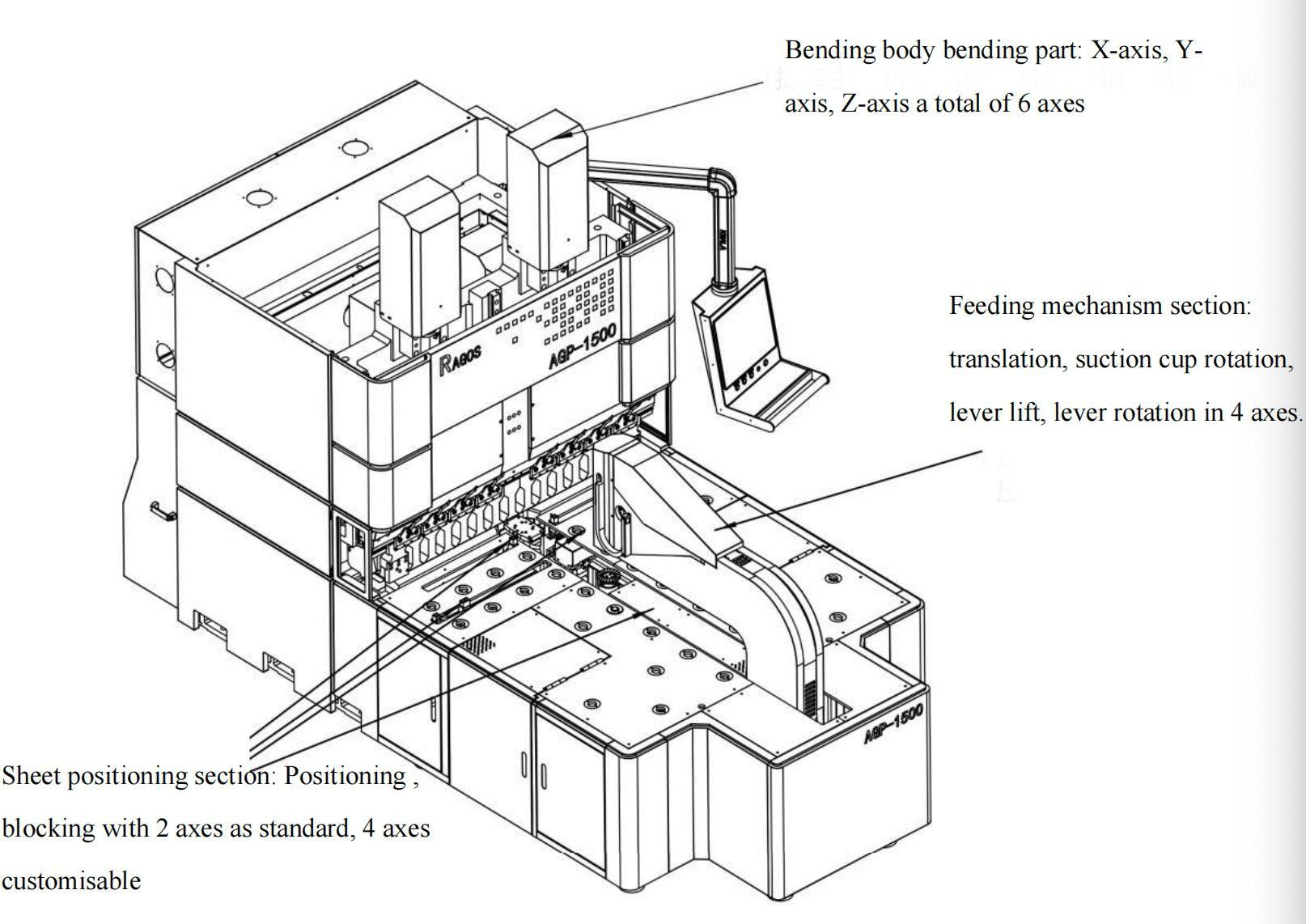

2. Axis Configuration Description The conventional standard configuration has a total of 12 axes, the bending body section has 6 axes of X, Y and Z axes. The feeding mechanism is in translation, lower platen rotation, press bar lift and press bar rotation in 4 axes. Sheet positioning section: positioning and staging in 2 axes. Customized machine configuration with a total of 14 axes, the bending body section has 6 axes of X, Y and Z axes. The feeding mechanism is in translation, lower platen rotation, platen lift, platen rotation and custom lower platen lift for a total of 5 axes. The sheet positioning section: positioning, staging, customized rear staging in a total of 3 axes. |

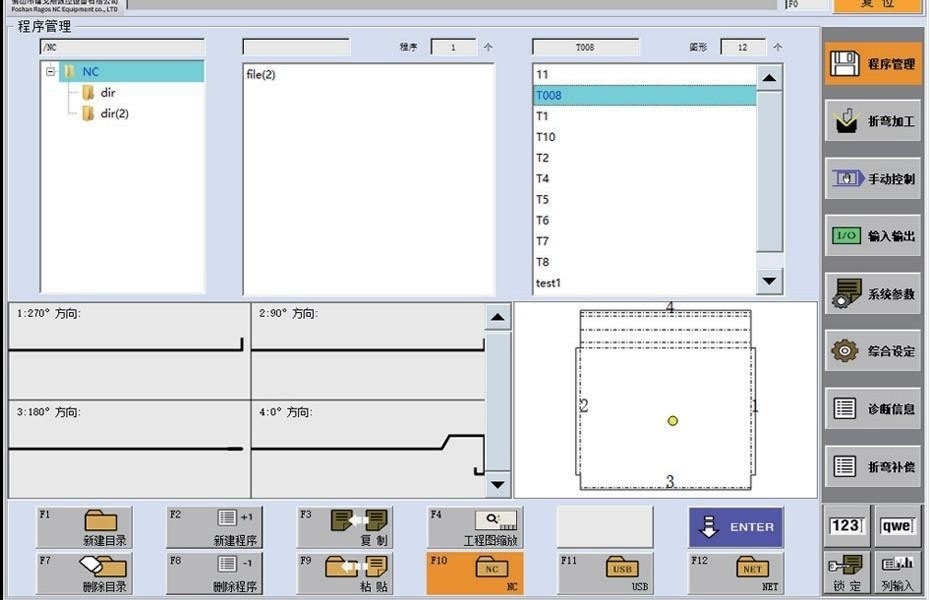

3. CNC Control System

(II)Main Bending Process

1.Bending Process Description

Bending Process Requirements:

1. The surface of the material to be bent cannot have downward protrusions, as this may cause interference with the workbench and prevent automatic bending.

2. For suction cup bending centers, when bending all four sides of the material, there should not be large openings in the center of the material, as this will prevent the suction cups from holding the

material in the center. For pressing rod bending centers, there should be a space reserved for pressing the material.

3. The distance from the edge of the hole to the bending edge should be ≥ 5mm. Otherwise, there may be a pulling effect after bending (the larger the thickness of the material, the larger this dimension should be).

4. After forming, the bending direction can only be bent in one direction, ultimately facing downward.

5. Whether the bending center can bend automatically depends on the bending process and sequence of the part. The final decision will be based on the approved drawing.

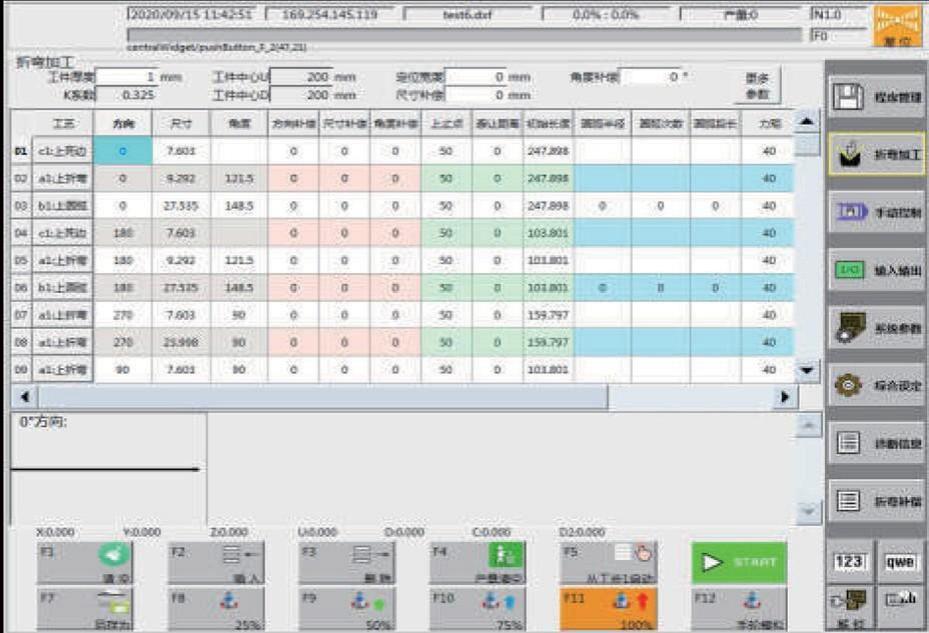

6. The dimensions of the bending tools in the figure on the right are standard, and can be customized according to customerrequirements.

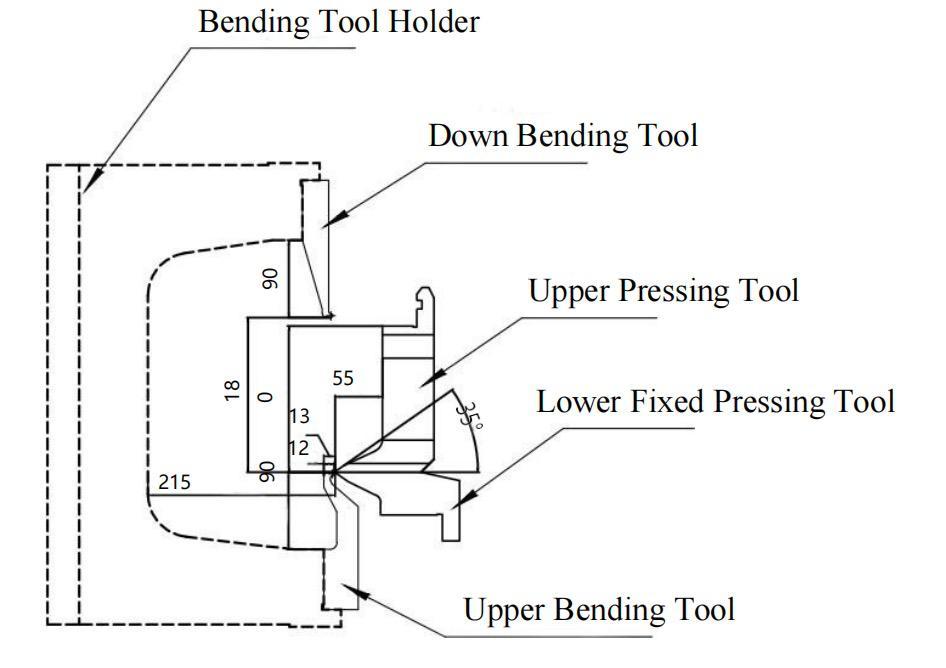

7. The figure above shows some examples of upper and lower bending. The actual dimensions will be based on the size of the product.

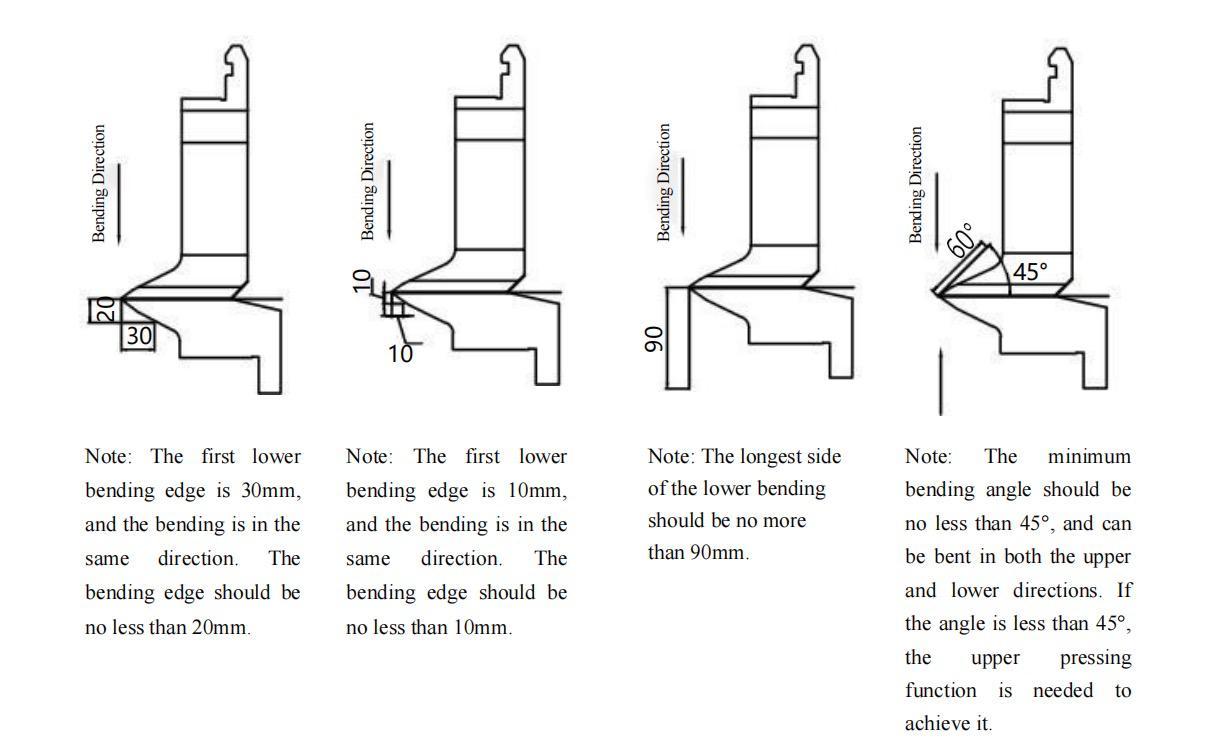

Basic Bending Dimension Requirements for Some Parts

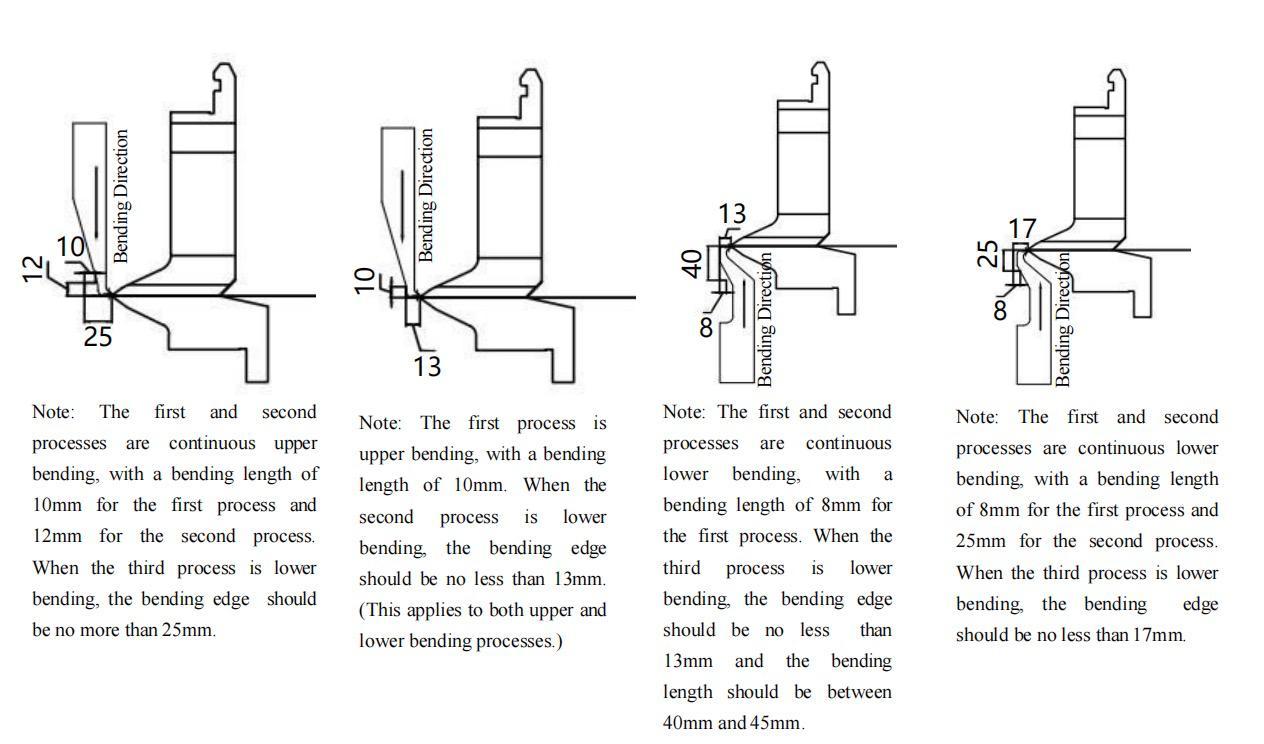

Diagram of partial reverse direction bending requirements

Diagram of partial reverse direction bending requirements

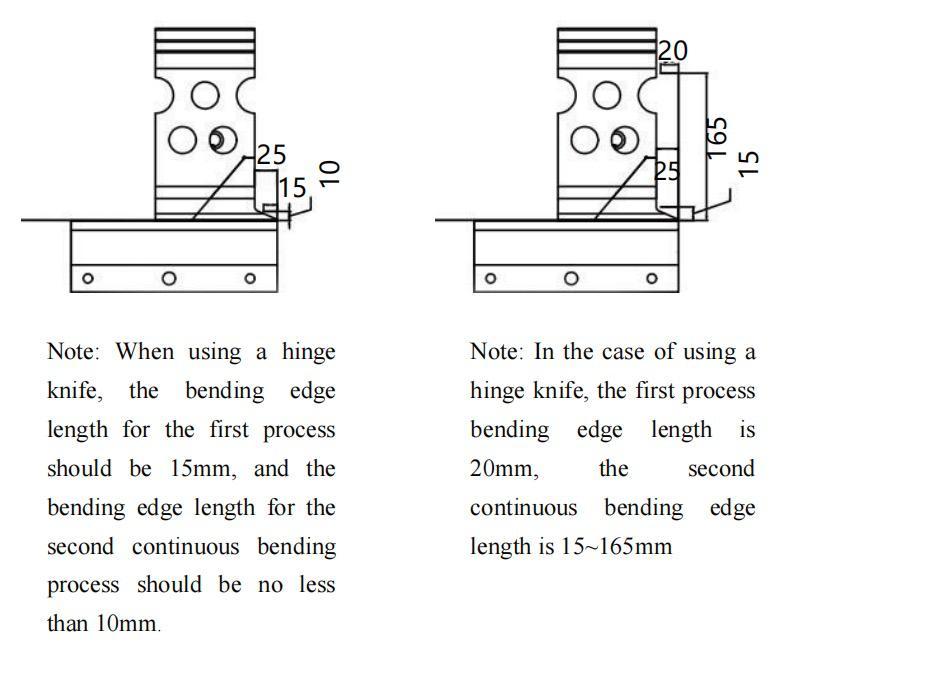

Requirements for the use of partial hinge knives

Requirements for the use of partial hinge knives

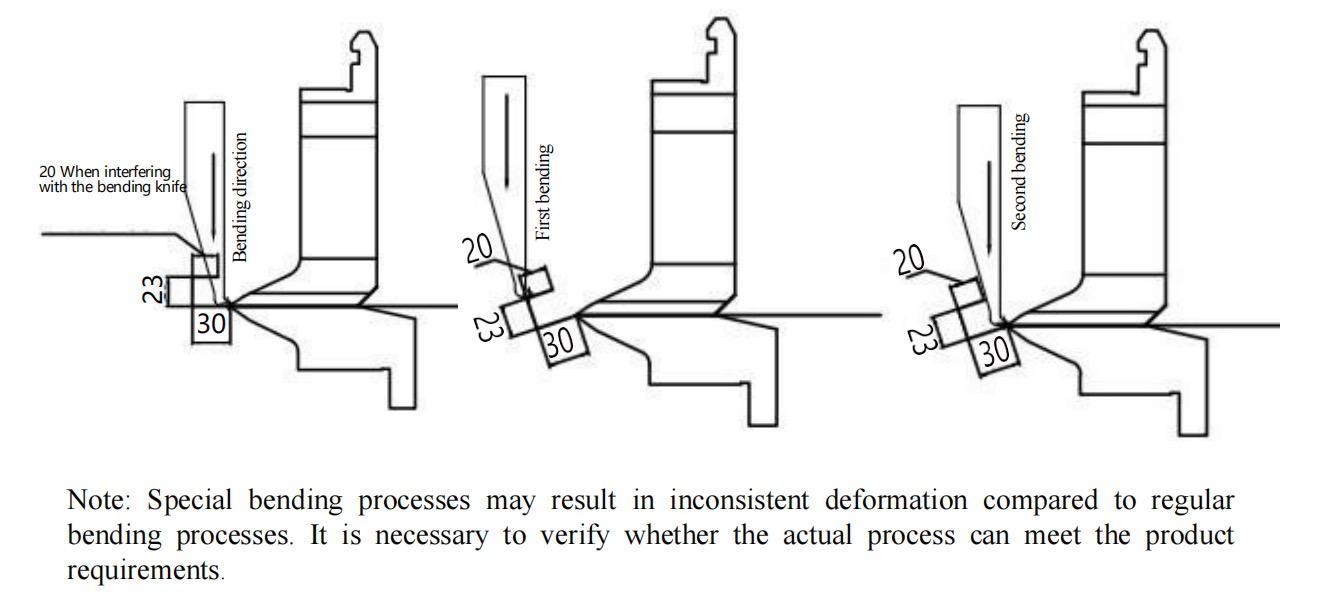

Special bending process

Special bending process

(iii)Bending Size Range

1. Minimum range of bending edge sizes for the AG series

|

Plate thickness(mm) |

Minimum Size(mm) |

|

0.3 - 0.6 |

4 |

|

0.7 - 1.0 |

5 |

|

1.1 - 1.2 |

6 |

|

1.3 - 1.5 |

8 |

|

1.6 - 2.0 |

10 |

2. Tolerance Range for Bending Size and Angle in AG Series

|

Length(mm) |

300 - 500 |

501 - 800 |

801 - 1000 |

1001 - 1200 |

1201 - 1500 |

1501 - 1800 |

1801 - 2000 |

|

Dimensional tolerance at both ends(mm) |

±0.1 |

±0.1 |

±0.1 |

±0.1 |

±0.15 |

±0.25 |

±0.25 |

|

Angular tolerance(°) |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

±0.75 |

±0.75 |

|

Diagonal tolerance(mm) |

±0.5 |

±0.5 |

±0.5 |

±0.5 |

±0.75 |

±0.75 |

±0.1 |

(iv)Main technical parameters

|

Bending length |

mm | 2000 |

|

Sheet length |

mm | 2100 |

|

Sheet width |

mm | 1250 |

|

Bending height |

mm | 170 |

|

Total bending length |

mm | 200 |

|

Minimum formed internal dimensions on all four sides |

mm | 360×180 |

|

Double - sided minimum formed internal dimensions |

mm | 180 |

|

Minimum radius of circle |

mm | 1.2 |

|

Fastest continuous bending speed |

s | 0.5/Knife |

|

Distance between upper and lower knives |

mm | 180 |

|

Bending angle |

° | 0 - 360° |

|

Maximum material thickness |

mm | Aluminum plate:2.0 |

| Carbon steel:1.5 | ||

| Stainless steel:1.2 | ||

|

CNC control system |

- | Star300 - LGx |

|

Operating systems |

OS | Win7 + OS |

|

Number of axes |

axes | 13 axis as standard; 14 axis customised |

|

Machine dimensions - L |

mm | 4580 |

|

Machine dimensions - W |

mm | 2400 |

|

Machine dimensions - H |

mm | 2950 |

|

Machine weight |

kg | 13800 |

|

Total power |

KW | 44.65/45.05 |

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine