CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

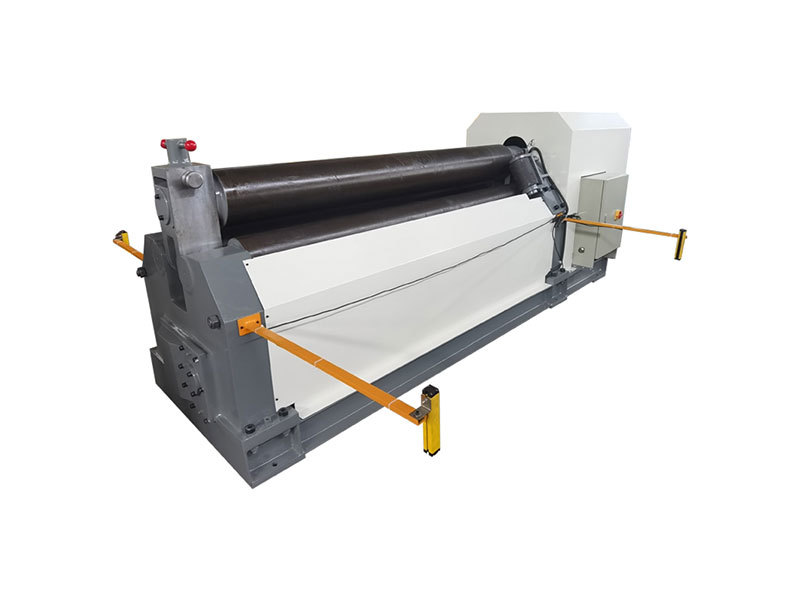

KW12 Series Sheet Metal Rolling Machine

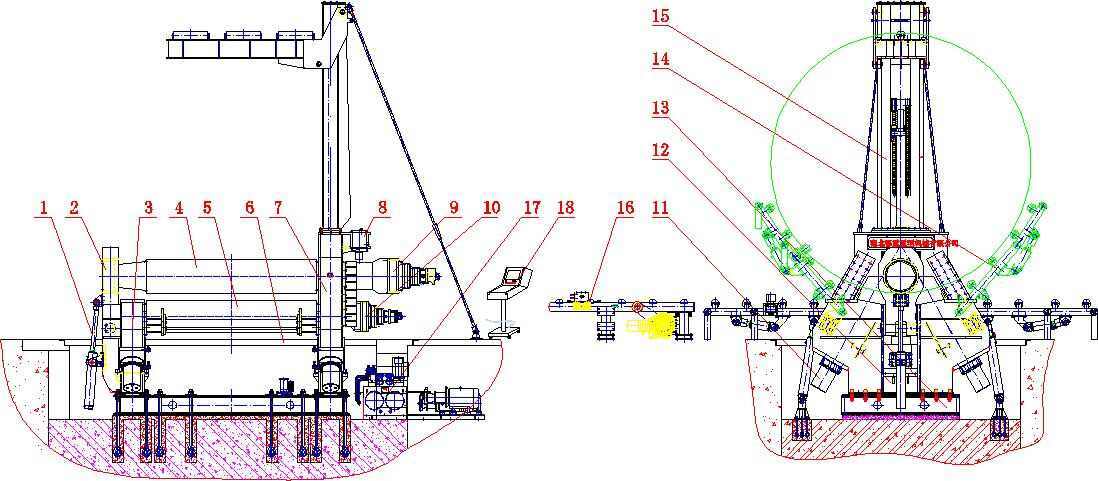

Equipment Functions and Working Principle:The KW12 Series Sheet Metal Rolling Machine (taking KR12CNC-60×6000 as an example) is a four-roller plate rolling machine, mainly used in the manufacturing of cylindrical pressure vessels. It features functions of roll rounding, pre-bending, circle correction, and rough leveling. The upper roller is the driving roller, which drives the lower and side rollers through friction with the sheet and provides rolling torque.

Keywords:

Series Sheet Metal Rolling Machine

|

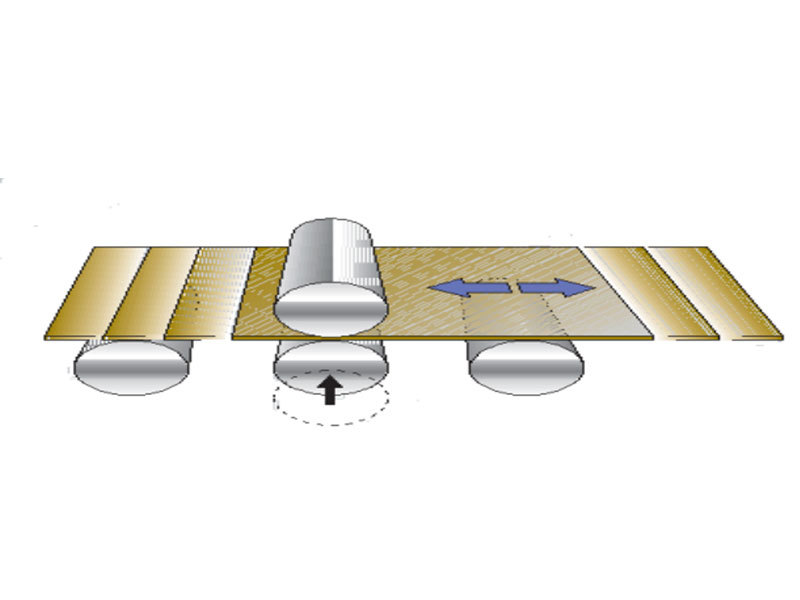

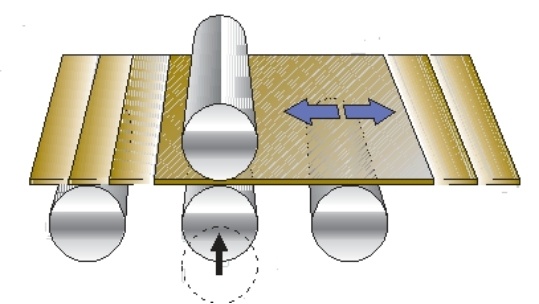

Equipment Functions and Working Principle: The KW12 Series Sheet Metal Rolling Machine (taking KR12CNC-60×6000 as an example) is a four-roller plate rolling machine, mainly used in the manufacturing of cylindrical pressure vessels. It features functions of roll rounding, pre-bending, circle correction, and rough leveling. The upper roller is the driving roller, which drives the lower and side rollers through friction with the sheet and provides rolling torque. The lower roller lifts vertically, and the side rollers lift obliquely, with a synchronization accuracy error of less than 0.15mm. For pre-bending, the lower roller rises to clamp the sheet, and the side rollers tilt upward to complete the pre-bending of the plate end, enabling small arc bending without additional pre-bending equipment. |

|

Main Technical Parameters: Model KR12CNC-60×6000, four-roller design, roll length 6100mm, upper roller diameter 880mm, lower roller 840mm, side roller 700mm; Maximum rolling thickness 60mm, yield limit ≤245MPa, remaining straight edge length ≤2-2.5 times the thickness, maximum pre-bending thickness 50mm; Upper roller driven by 1 independent hydraulic motor + planetary reducer direct coupling, maximum rolling speed approximately 4m/min; Main motor power 45KW, power supply 380V three-phase 50Hz, equipped with PLC control system, with 4 groups/2 groups of digital displays for side roller/lower roller positions respectively. |

|

Structural Composition and Core Configuration: Structure includes frame (base, fixed side frame, overturning side frame), upper roller device, main transmission device, lower roller device, side roller device, balancing device, overturning device, hydraulic system, electrical system, etc.; Core configuration: Rollers made of 42CrMo high-quality alloy steel (HB260-300 after heat treatment), hydraulic valves from Yuken, main electrical components, PLC and screen from Siemens, seals from Taiwan Yx and Japan NOK, bearings from well-known brands. |

|

System Features and Advantages: Hydraulic system: Adopts superimposed valve series with simple pipelines, including overpressure protection, synchronization circuit (accuracy 0.15mm) and speed control circuit, working pressure 19.5MPa; Electrical system: Includes control cabinet, console and handheld button box, with main motor overload and short-circuit protection, PLC control reduces relays for high reliability; Advantages: Durable linear guideway system, high-precision electronic balance synchronization control, heat-treated rollers with high hardness, hydraulic system overload protection, and systems like automatic lubrication, low oil level alarm, and safety stop. Large-size bearings enhance structural stability. |

Main specifications of the four-roller rolling machine.

|

No. |

|

Items |

Parameters |

|

1 |

|

Model |

KR12CNC-60×6000 |

|

2 |

Roller |

Number of rolls |

4 |

|

Roll length |

6100㎜ |

||

|

Upper roller Dia |

880㎜ |

||

|

Lower roller Dia |

840㎜ |

||

|

Side roller Dia |

700㎜ |

||

|

Full load minimum Dia |

4000㎜ |

||

|

Roller material |

Tested and verified Heat treated high strength forged steel |

||

|

Roller heat treatment |

HB246~302 |

||

|

3

|

Drive |

Drive roll |

Upper drive |

|

Driver system |

1 independent hydraulic motor + planetary deceleration directly coupled to the roller |

||

|

Max rolling speed |

~4m/min |

||

|

Circumferential compensation velocity |

Automatic hydraulic compensation system, no energy loss |

||

|

4 |

Rolling requirement |

Max thickness |

60mm |

|

Yield limit of sheet |

σs≤245MPa |

||

|

Length of the remaining straight edge |

≤2-2.5 thickness |

||

|

Maximum prebending plate thickness |

50mm |

||

|

5 |

Electric |

Main motor |

45KW |

|

Voltage and frequency |

380V, 3 phase, 50Hz |

||

|

Controller |

PLC |

||

|

Side roll position display |

4 groups of digital display |

||

|

Lower roll position display |

2 groups of digital display |

|

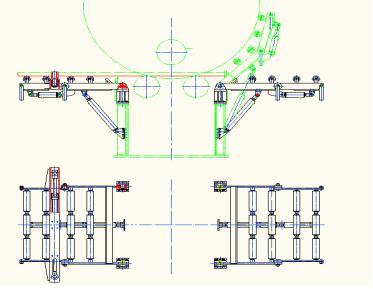

1.Tip over the oil cylinder |

2.Tip over the rack |

|

3.Left Rack |

4.upper roll |

|

5.side roll |

6.lower roll |

|

7.Right rack |

8.Balancing device |

|

9.Upper roller drive device |

10.Lower roll drive (optional) |

|

11.Side roll cylinder |

12.lower roller cylinder |

|

13.Base |

14.Side bracket (optional) |

|

15.Upper bracket (optional) |

16.Electric Feeding platform (optional) |

|

17.Hydraulic System |

18.Electronic Control System |

1. Specification of the rolling machine.

The machine belongs to four roller bending machine, used for cylinder pressure vessel manufacturing industries, it has function of roll round, pre-bending, correct the circle, with coarse leveling function.

The upper roller is the main transmission, leading the lower roller and the side roller move by friction between the sheet plate and the upper roller, meanwhile, the upper roller provides torque for rolling rollers.

The upper roller is the active roller by hydraulic transmission, lower roller and the accessories, both sides turn plane and supporting roller lifting are driven by hydraulic pressure.

The lower roller use vertical lifting, the side roller use tilt lifting, so the synchronization precision error is less than 0.15mm.

To make prebending, the lower roller rising and clamping the sheet plate, the side roller inclined upward, plate end pre-bending done.

According to the arrangement of the side roller to adjust the position of the two sides, four roller rolling machine can do symmetric or non-symmetric bending, so the machine can be a rolled ideal very small arc straight edge into theory of surplus. If compared with the symmetrical three roller bending machine, four roller rolling machine do not need to use pre-bending plate press any more.

The lubricating point of the machine use cut-up arrangement.

The four-roller rolling machines’ control system adopted Japan OMRON intelligent high-speed PLC industrial control machine, the system can control lower roller, and the other roller accessories.

The lower roller and the two side roller’s displacement sensor using encoder, so the action design of the sensor is reasonable, which can guarantee the service life.

All bearings used in the four-roller rolling machine are required to adopt the most advanced technology, the most well-known manufacturers of leading products.

Hydraulic cylinder with accuracy manufacturing, good sealing effect, so the cylinder reduce the pressure relief and leakage of sealing device, in addition, all sealing accessories imported from abroad.

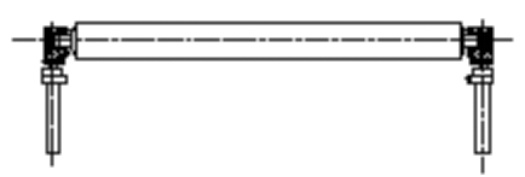

A conical device used to roll cones.

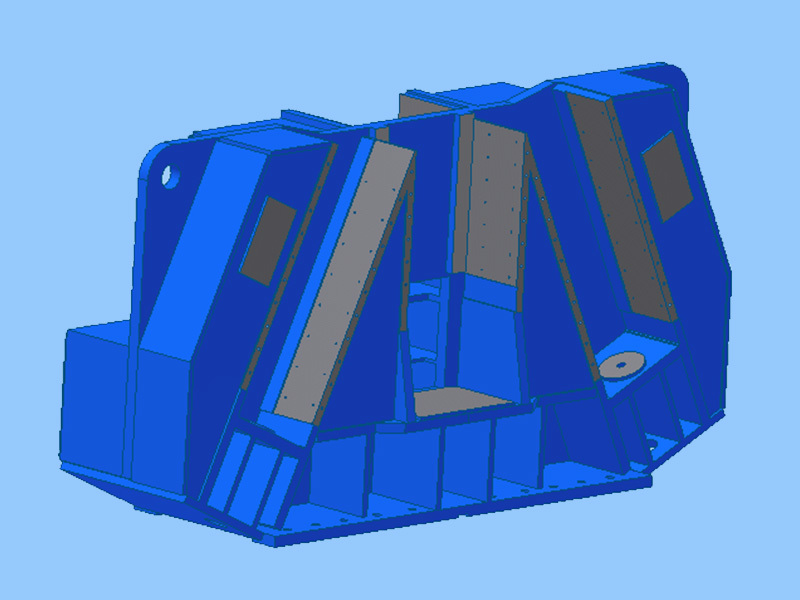

2.Main structure of the four-roller rolling machine.

This equipment is composed with machine frame, upper roller device, main driving device, lower roller device, side roller device, balancing device, a tilting device, hydraulic system, electrical system, display system and lubrication system, etc.

|

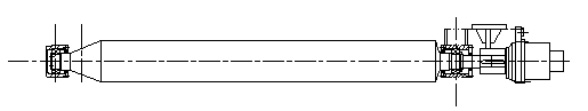

Upper roller device. The upper roller is drived by main transmission device to rotary motion, and both ends holds by SP - 1 sliding bearing. The driving end connect the main transmission by flat key and open gear for transmission torque. The overturned end equiped with steel sleeve. The upper roller made of superior alloy steel of 42CrMo, thermal refining with HB260-300. |

|

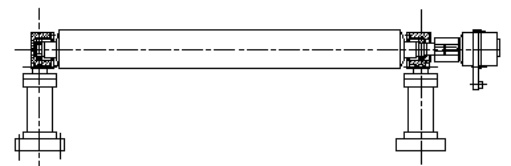

The main transmission device. The main transmission device use hydraulic motor, planetary reducer to transmit torque to the upper roller. In addition, there also equiped a electrical hydraulic push rod brake on the high-speed bearing of the speed reduction gear. The lower roller device. The lower roller holding on aligning bearings, also, the bearing seat is arranged on the two sides of frame rail, and the bottom connected with piston of the cylinder. Bearing seat can be rise or drop on guide rail by effection. Thrust of the piston can be operated by hydraulic control system at will according to the request of force to clamped she sheet plate with upper and lower roller. |

|

The side roller device. Side roller holding in the bearing seat, and the bearing seat arranged on the two sides of frame rail, and the bottom connected with piston of the cylinder. Bearing seat can be rise or drop on guide rail by effection. Thrust of the piston can be operated by hydraulic control system at will according to the request of force to clamped she sheet plate with upper and lower roller. Thermal refining with HB260-300. |

|

The balance device. Balance device using tensioning screw climbing mechanism, when the overturning frame come away from the upper roller bearing, the upper roller will dropped due to the action of gravity on the end of roll, to make the upper roller in a horizontal position, the fixing side outer end of the tail rod is provided with a balancing device and is fixed on the base with bolt. |

|

The overturned device. The overturned device use the oil cylinder, the hinge to drive the overturning frame overturn disengaged from the upper roller bearing, so that products can be take out. |

The lateral support device(optional)

Lubrication system.

The main reducer and side roller drive reducer used oil tank splash lubrication, natural cooling, when the environment temperature fit -10℃ to 0℃, please use N46 or N68 oil, when the environment temperature fit 0℃ to 40℃, please use N68 or N100 or N150 or N220 oil. The other lubrication points using the manualgrease gun to lubricating. The working medium is grease ZGN40 - 1(for winter use), and ZGN40 - 2(for summer sue), every one or two times of lubricating in one working day.

3.The hydraulic system.

Introduction.

The hydraulic system consists of gear pump, valve group, fluid connectors, hydraulic auxiliary parts, etc. Besides, we choose superposition valve series for the hydraulic valve. Simple pipe arrangement, make it convenient to maintenance and debugging.

The hydraulic system is composed of three kinds of circuit, there are over pressure protection and pressure regulating circuit, synchronization loop, and speed loop components. The pressure regulating circuit system works through the main relief valve pressure.The system working pressure is 19.5Mpa.

Synchronous circuit through the shunt throttle valve on roller rise and fall of coarse step shunt synchronization, throttle exam up and down regulating displacement sensor detection, and the upper roller synchronous positioning accuracy is 0.15mm.

The speed loop control overturning side machine overturned, reset, and adjust circuit with throttle speed through the throttle valve.

Various of protection measures.

There are overflow valve to protect limited rise and fall of upper roller.

4.The electrical system.

The four roller rolling machines’ electrical control system consists of an electric control cabinet, console, and hand held button box operation. Power supply 380V / 60Hz. The main switch has overload protection function and short circuit protection for the main motor. Reversing of motor is controlled by the AC contactor, the control circuit use PLC programmable controller system, less relay, operation reliable, and own long service life. The control cabinet is provided with a finished product rolling process of all the control button and indicator, to master machine operation control and working state control.

5.Attachments of the machine & machine key components list.

|

No. |

Name |

Origin |

|

1 |

Gear pump |

Hefei, China |

|

2 |

Hydraulic valve |

Yuken |

|

3 |

Compost bearing |

Wafangdian, China |

|

4 |

Working roll |

North steel of China |

|

5 |

Sealing element |

Yx, Taiwan |

|

6 |

Main electrical components |

Siemens |

|

7 |

Main hydraulic motor |

Siemens |

|

8 |

Cylinder seal |

NOK |

|

9 |

PLC |

Siemens |

|

10 |

Screen |

Siemens |

6.Advantages of 4-rollers plate rolling machine.

|

Advantages |

|

|

Liner guideway system, reliable and endurable. |

Lower voltage control system. |

|

Electronic balance synchronization control system(accuracy ± 0.15mm). |

Automatic alarm system for lower oil level and filter clogged. |

|

Double power roller with 2 gearbox and 2 hydraulic motor. |

Safety stop system, to stop all moving parts of the whole machine. |

|

Surface of roller with heat treatment, which hardness can be HB260-300. |

Liner guideway system, more reliable and more endurable. |

|

Hydraulic system to prevent overload. |

Large size axis bearings, make the whole structure more stable. |

|

Automatic lubrication system. |

All moving parts use hydraulic power, more reliable and more endurable. |

7. Spare part list

|

Name |

Number |

|

Foundation bolt |

6 |

|

Nut |

6 |

|

Compound gasket |

20 |

|

O-rings |

20 |

|

Grease gun |

1 |

|

Oil gun |

1 |

|

Instruction Manual |

1 |

KW12CNC-60x6000 Four Roller Plate Rolling Machine

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine