CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

KD-BB1308D Manual Deburring Machine

● Manual deburring machine with vacuum table ● Deslagging ● Deburring ● Edge Rounding ● Oxide layer removal ● Metal Polishing

Keywords:

Metal Deburring Machine

Main configuration and technical parameters of KD-BB1308D:

(I) Main technical indicators:

|

Number of grinding heads |

1 |

|

Type of grinding head |

disc type / cup shape |

|

Workbench |

1,300 x 800 mm |

|

Vacuum area |

300 x 250 mm |

|

Abrasive drive motor |

230 V / 0.75 kW / 4 A |

|

Grinding plate diameter |

150 mm |

|

Grinding head can rotate |

180° |

|

Maximum machined workpiece thickness |

60 mm |

|

Minimum processing size |

5,050 mm |

|

Table Height |

960 mm |

|

Equipment noise |

85dB |

|

Weight |

270kg |

|

Chamfer range |

R0. 1~0. 3 |

|

Processing and grinding consumables |

sand plate and grinding piece roller |

|

Core Advantages and Functions Easy to operate with parameter memory function; capable of edge rounding, removing burrs, slag, oxide skin, and corner rounding; equipped with automatic magnet cleaning and adsorption cavity automatic cleaning; high-pressure vacuum adsorptive worktable suitable for small parts processing. |

|

Conveying Mode and Application Scope Adopts turbine vacuum adsorption and conveying via high-damping wear-resistant rubber belt; applicable to handling oxide skin, slag/burrs from laser, flame, plasma cutting, as well as burrs and sharp edges from NCT, stamping, cutting processes, and can process materials such as stainless steel, carbon steel, and copper. |

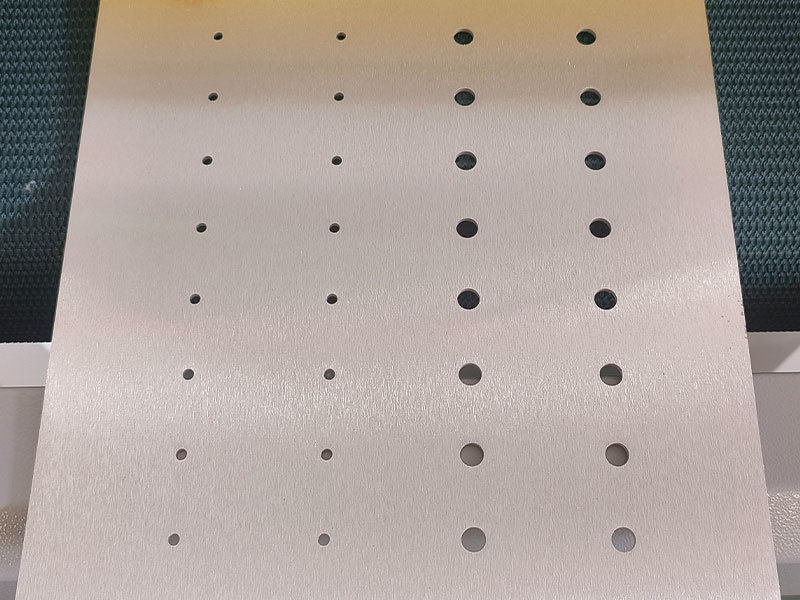

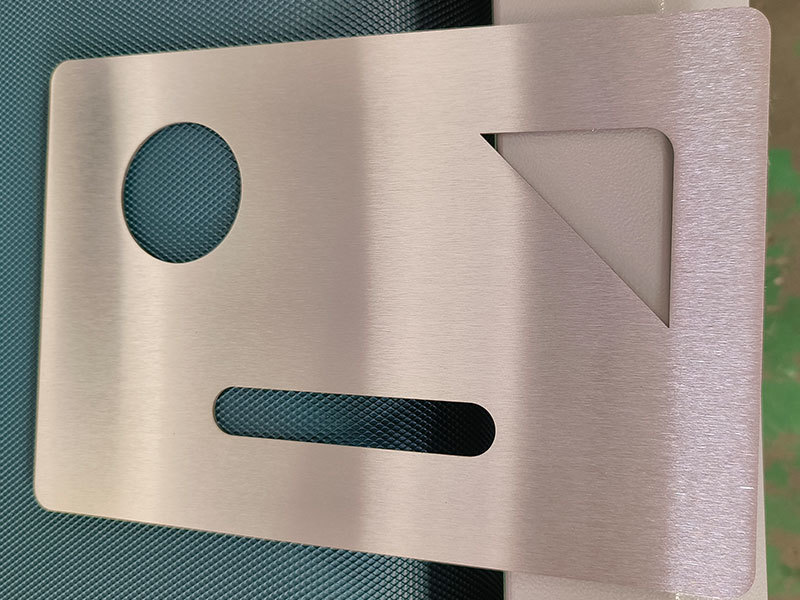

| General usage effect comparison chart | |||

|

|

|

|

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine