CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

Sheet Metal Straightening Machine

Featuring by parallel multi-rollers, screw rod pressing, intensive support and other technologies, the Equipment may be employed to meet the leveling requirements of sheet materials and flat parts. The quadruple leveller structure is utilized.

Keywords:

Sheet Metal Straightening Machine

I. Brief Introduction and Main Features of the Equipment:

1.Featuring by parallel multi-rollers, screw rod pressing, intensive support and other technologies, the Equipment may be employed to meet the leveling requirements of sheet materials and flat parts.

2. The quadruple leveller structure is utilized.

II.50-800-19 Hydraulic Precision Leveling Machine:

1. The main technical parameters are shown below:

|

Thickness of the levelable plate |

0.8-20mm |

|

Width of the levelable plate |

≤1000mm (opening width of the Equipment: 1100mm) |

|

Diameter/quantity of leveling rollers |

Φ80 Upper 9+ lower 10=19rolls |

|

Drive mode of the leveling roller |

AC gear motor * 2 sets |

|

Feed rate |

0-10m/min, adjustable frequency conversion. |

|

Speed adjustment |

Frequency Converters * 2 sets Synchronization of upper and lower rollers for electronic speed regulation Automatic stop function against overload |

|

Measurement and display of the roll gap |

Displacement sensors * 4 sets Touch screen and PLC electric controller |

|

Adjustment of the roll gap |

Hydraulic Locking,Servo Limit and Numerical Control Adjustment |

|

Main unit structure |

Two beams and four columns Drive by the left side Cleaning and maintenance of the leveling roller by the right side |

|

Leveling accuracy (flatness) |

0.1mm /m2 |

|

Yield Strength |

235Mpa |

2. Working principle diagram of the leveller:

3. Power and environmental requirements of the leveller:

|

Item |

Explanations |

Remarks |

|

Power voltage |

Three-phase AC380V, ±10% |

|

|

Power frequency |

50Hz, ±1% |

|

|

Total power consumption |

Approximately 35KW |

|

|

Control voltage |

AC220/DC24 |

|

|

Ambient temperature |

1~40℃ |

|

|

Altitude |

below 1,000m |

|

|

Relative humidity |

20-80% (No condensation, no dew formation) |

|

|

Protection level |

IPX4 |

III. Detailed Description of Key Performance:

|

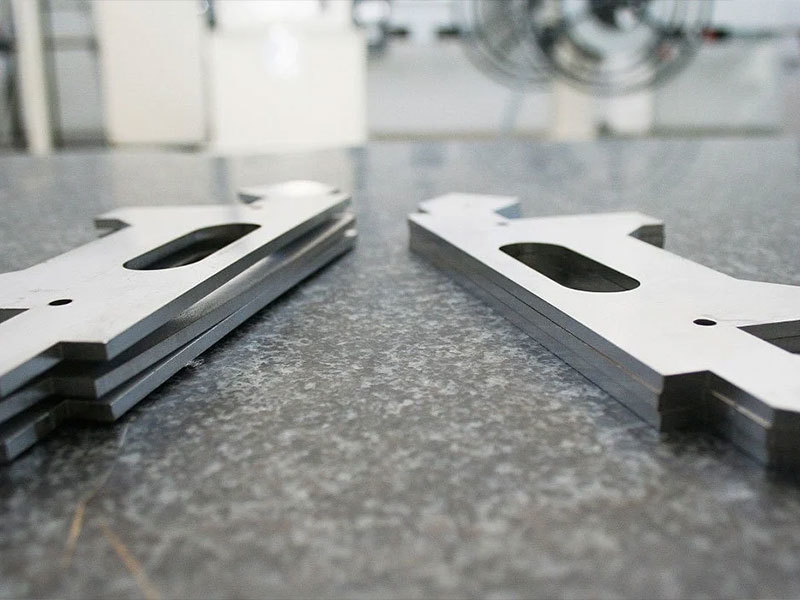

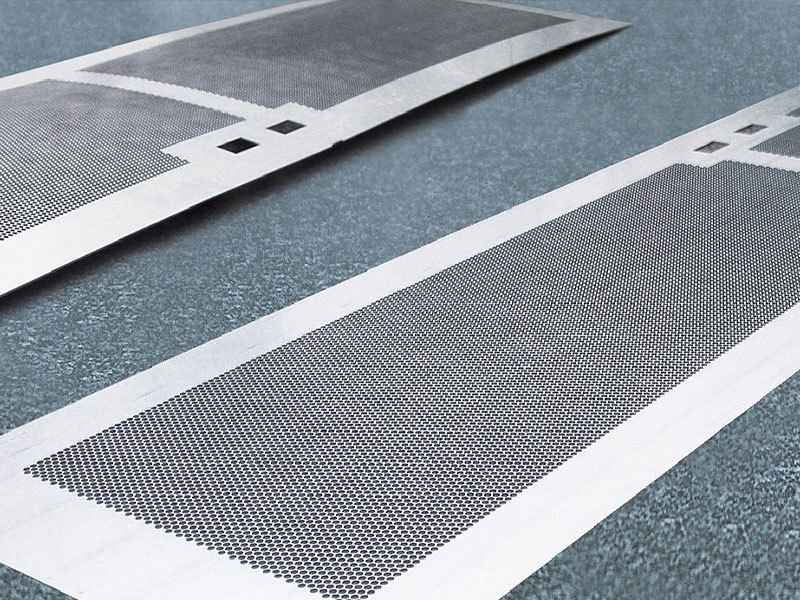

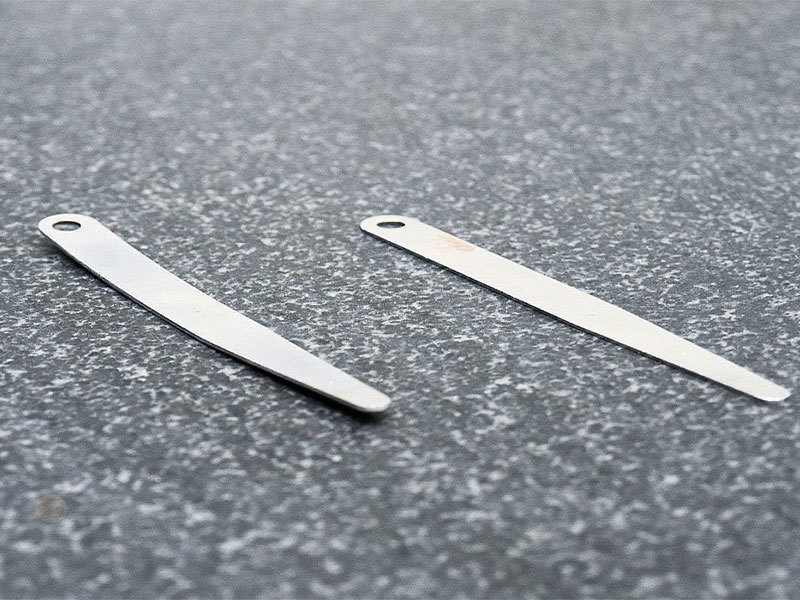

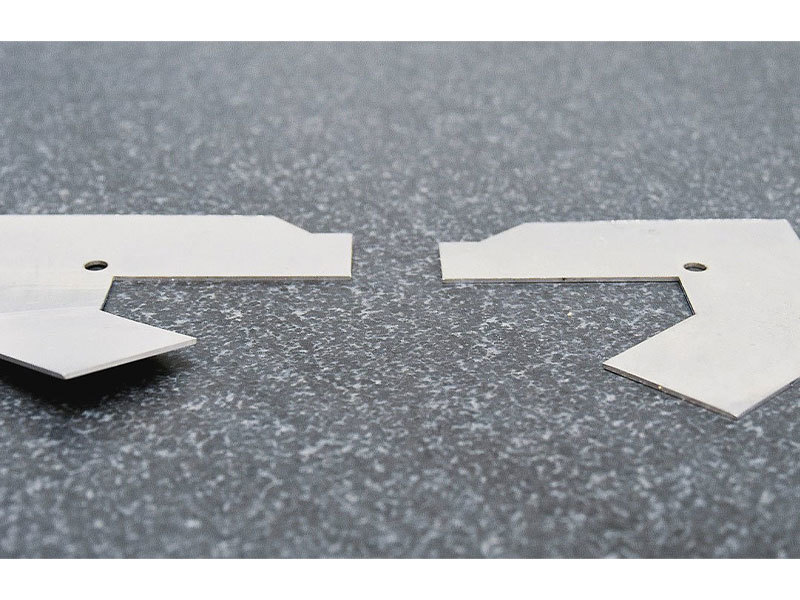

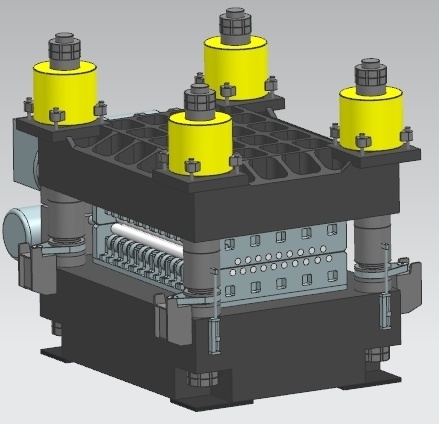

1. The leveling roller is made of GCr15 bearing steel (see Figure 1). After heat treatment, the surface hardness reaches HRC58-62, and then hard chromium plating and rust prevention treatment are carried out. There are totally 15 Φ125mm leveling rollers, with 7 ones in the upper row and 8 ones in the lower row. |

|

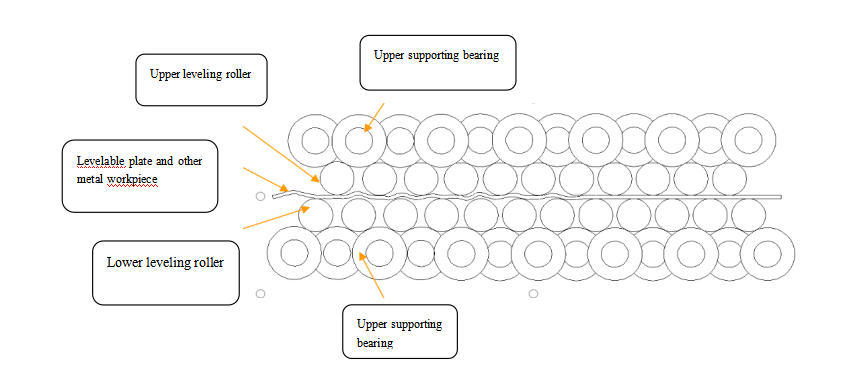

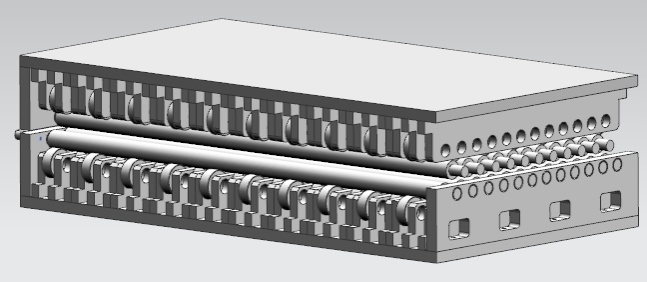

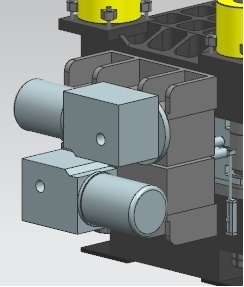

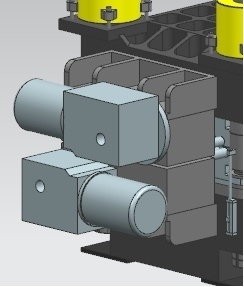

2. The upper and lower leveling roller groups are supported sequentially by specially designed support bearings for each leveling roller (see Fig. 2 and Fig. 3) Thereby preventing bending deformation of the leveling roller after being subjected to force, and the supporting rollers can be adjusted separately. This is commonly known as the roller system form of parallel rollers and quadruple levelers. |

|

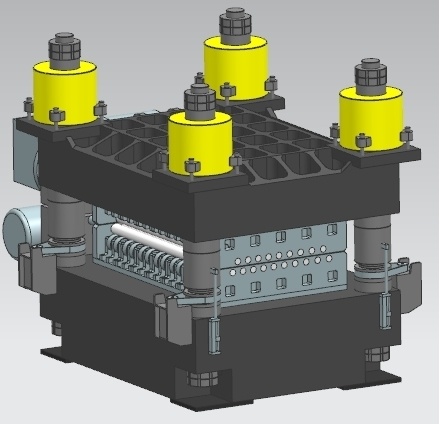

3. By using the four hydraulic columns of the upper and lower beams (see Figure 4) The inlet and outlet roller gaps between the upper and lower leveling roller groups are locked, and the inlet and outlet roller gaps remain unchanged regardless of whether there are sheet metal parts passing through the machine. Traditional and old-fashioned ordinary leveling machines adjust the front and rear roller gaps using use screws without pre-tensioning devices. Therefore, the frame body and the front and rear roller gaps are constantly changing during the leveling process of sheet metal parts, resulting in unsatisfactory leveling effects. |

|

4. The power section adopts two 30kW reducer motors (see Figure 5) with a designed maximum leveling speed of 10m per minute. |

|

5. The multi-axis gearboxes are designed and manufactured in-house, employing a gear transmission design scheme (see Figure 4), with each set of upper and lower leveling rollers corresponding to an upper and lower multi-axis gearbox. |

|

6. The clearance between the front and rear upper and lower rollers is adjusted by four servo motors on the four pillars, which are the limiting devices of the mechanical structure. The hydraulic locking device adopts four hollow oil cylinders fixed on the column (see Figure 7), and the supporting system adopts a hydraulic servo pump station. |

|

7. For the safety protection of the Equipment itself, the frequency converter is used to detect the current, and when the overloaded sheet parts are leveled, the Equipment will automatically stop for protection. |

|

8. The touch screen on the electrical cabinet allows for the configuration of working parameters for the leveller (see the Figure below). |

9. The maintenance window on the right side of the Machine can be opened to extract the leveling roller and supporting bearing assembly (upper and lower roller set), making maintenance and servicing more convenient without the need to dismantle the girder. The working rollers can be easily removed for cleaning by disassembling the right-side support wallboard of the upper and lower roller sets (for routine small-scale cleaning, a cloth soaked in alcohol is sufficient for wiping).

10. The overall design is compact with a small area, and generally does not require excavation of foundation pits. Especially the transmission part is simple and reliable (patent protection has been applied for), with high processing accuracy. The machine operates relatively quietly without significant noise with a wide leveling range. The leveling accuracy also far exceeds the mechanical industry standards, equivalent to imported leveling equipment. It also has the advantage of local after-sales service, low cost and fast response.

IV. Electric control and other auxiliary devices of the leveling machine

The electrical control part mainly includes an electrical cabinet, and the controller includes electrical components such as Delta brand frequency converters, PLCs, and touch screens, etc.

V. Configuration List of the Equipment:

|

Component Name |

Part Name |

Brand |

|

Mechanical portion

|

Leveling roller |

KNOPPO |

|

Axial bearing |

KNOPPO |

|

|

Wallboard |

KNOPPO |

|

|

Bottom plate |

KNOPPO |

|

|

Self-lubricating bearing |

KNOPPO |

|

|

Upright |

KNOPPO |

|

|

Upright mechanism |

KNOPPO |

|

|

Gearbox |

KNOPPO |

|

|

Axle Sleeve |

KNOPPO |

|

|

Hydraulic servo pump station |

KNOPPO |

|

|

Hydraulic cylinder |

KNOPPO |

|

|

Base |

KNOPPO |

|

|

Lubrication pump |

KNOPPO |

|

|

Main unit girder |

KNOPPO |

|

|

Shell platform |

KNOPPO |

|

|

Electrical section |

Main reducer motor |

Jiangsu GuoMao |

|

Adjustment servo motor |

Delta (standard configuration) |

|

|

Frequency converter |

Delta (standard configuration) |

|

|

PLC |

Delta (standard configuration) |

|

|

Touch screen |

Delta (standard configuration) |

|

|

Magnetostrictive displacement sensor |

JingYi |

|

|

Primary intermediate relay |

Omron |

|

|

LV apparatus |

Schneider |

|

|

Electric cabinet |

KNOPPO |

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

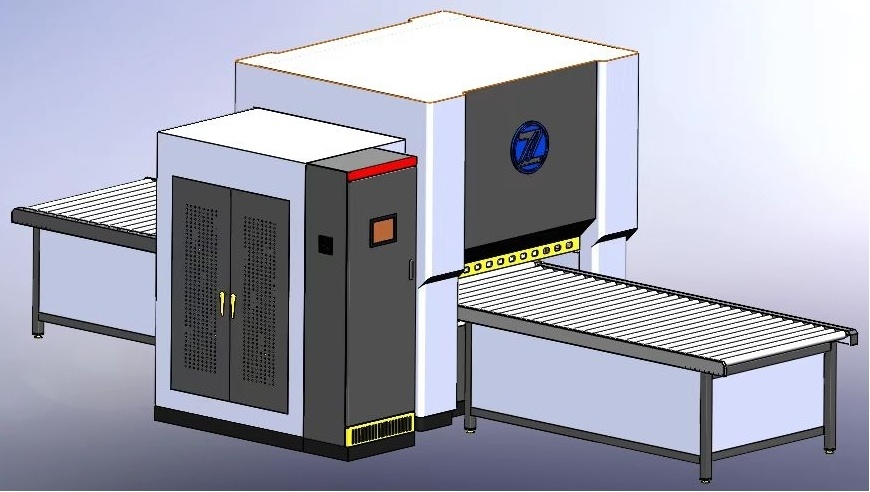

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine