CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

KC-M Continious Laser Cleaning Machine

Controllable parameters and high repeatability. To stabilize the mechanical structure and lens state, only need to stable the laser power and the process parameters must be repeatable, greatly improving efficiency.

Keywords:

Laser Cleaning Machine

|

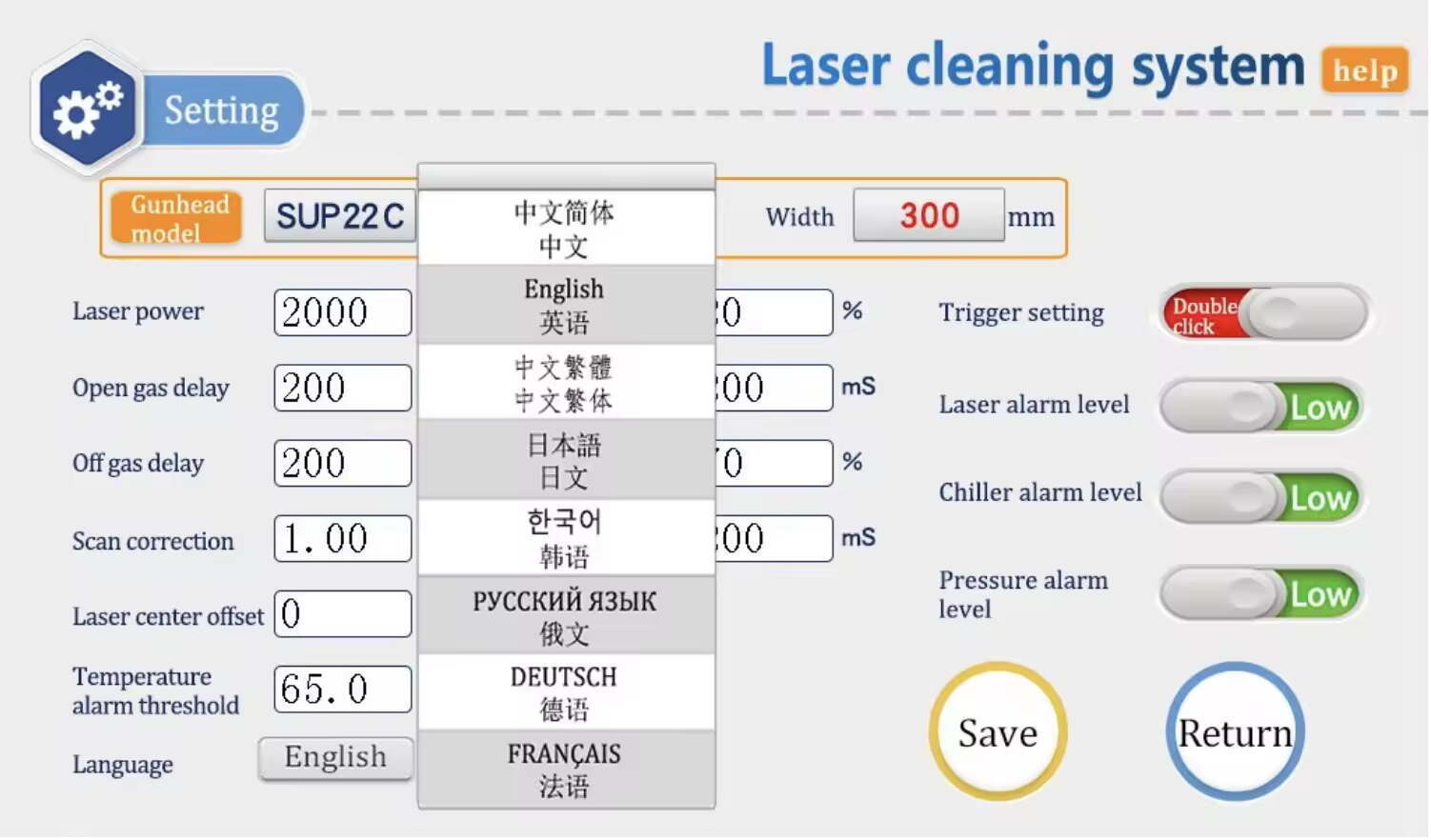

Operational Flexibility and Safety Assurance: Equipped with a handheld cleaning head, it is easy and flexible to operate, adapting to cleaning needs in different scenarios; multiple safety alarms are set to timely remind when the equipment is abnormal, ensuring operational safety. |

|

Stable Performance and Efficiency Advantages: Parameters are controllable with high repeatability. By stabilizing laser power and process parameters, the mechanical structure and lens state are kept stable, greatly improving cleaning efficiency; all parameters of the machine are visible, and the status is monitored in real time, facilitating early problem prevention and troubleshooting. |

|

Continuous Support of Cooling System: Adopts a dual-purpose water cooling system, which can cool the laser source and cleaning head at the same time, supporting 24-hour continuous work and ensuring the equipment maintains stable performance during long-term operation. |

Configuration Techinical parameters

|

NO |

Description |

Parameter |

|

1 |

Model |

KC-M |

|

2 |

Laser Power |

1000W 1500W 2000W 3000W 6000w |

|

3 |

Laser Type |

MAX / Raycus |

|

4 |

Central wavelength |

1064nm |

|

5 |

Line length |

10 M |

|

6 |

Cleaning efficiency |

12 m3/h |

|

7 |

Support language |

English, Chinese, Japanese, Korean, Russian, Spanish |

|

8 |

Cooling Type |

Water cooling |

|

9 |

Scanning Width (mm) |

10-300 |

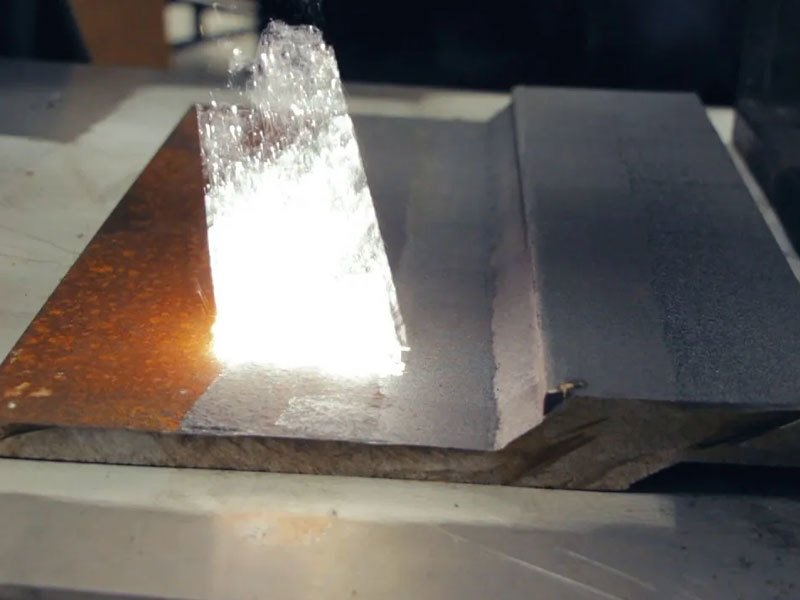

Laser cleaning machine before and after use:

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine