CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

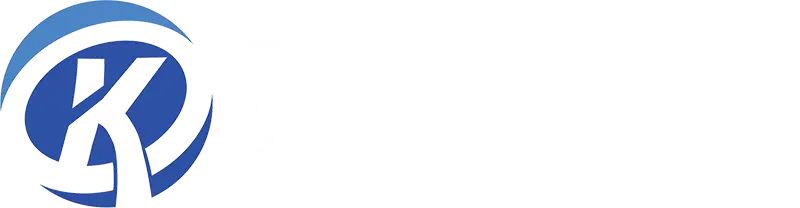

KT Series Tube Laser Cutting Machine

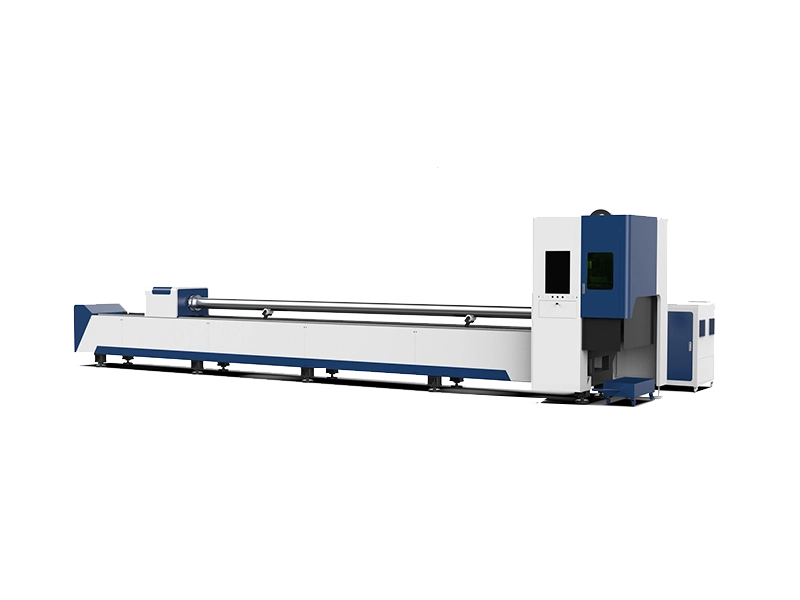

Automatic Electric Chuck: Driven by a claw DC motor, with sensitive, adjustable and stable clamping current. It has a wide clamping range and large clamping force, realizing non-destructive clamping and fast automatic centering. It features high transmission efficiency, long service life, and intelligent CNC self-centering function for precise control of clamping position, enabling flexible switching of tubes with different thicknesses and avoiding deformation of thin-walled tubes.

Keywords:

Fiber Laser Cutting Machine

|

Automatic Electric Chuck: Driven by a claw DC motor, with sensitive, adjustable and stable clamping current. It has a wide clamping range and large clamping force, realizing non-destructive clamping and fast automatic centering. It features high transmission efficiency, long service life, and intelligent CNC self-centering function for precise control of clamping position, enabling flexible switching of tubes with different thicknesses and avoiding deformation of thin-walled tubes. |

|

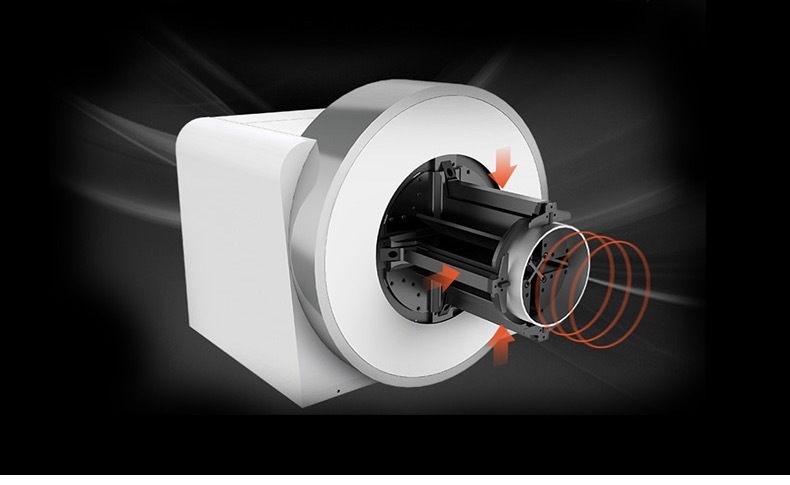

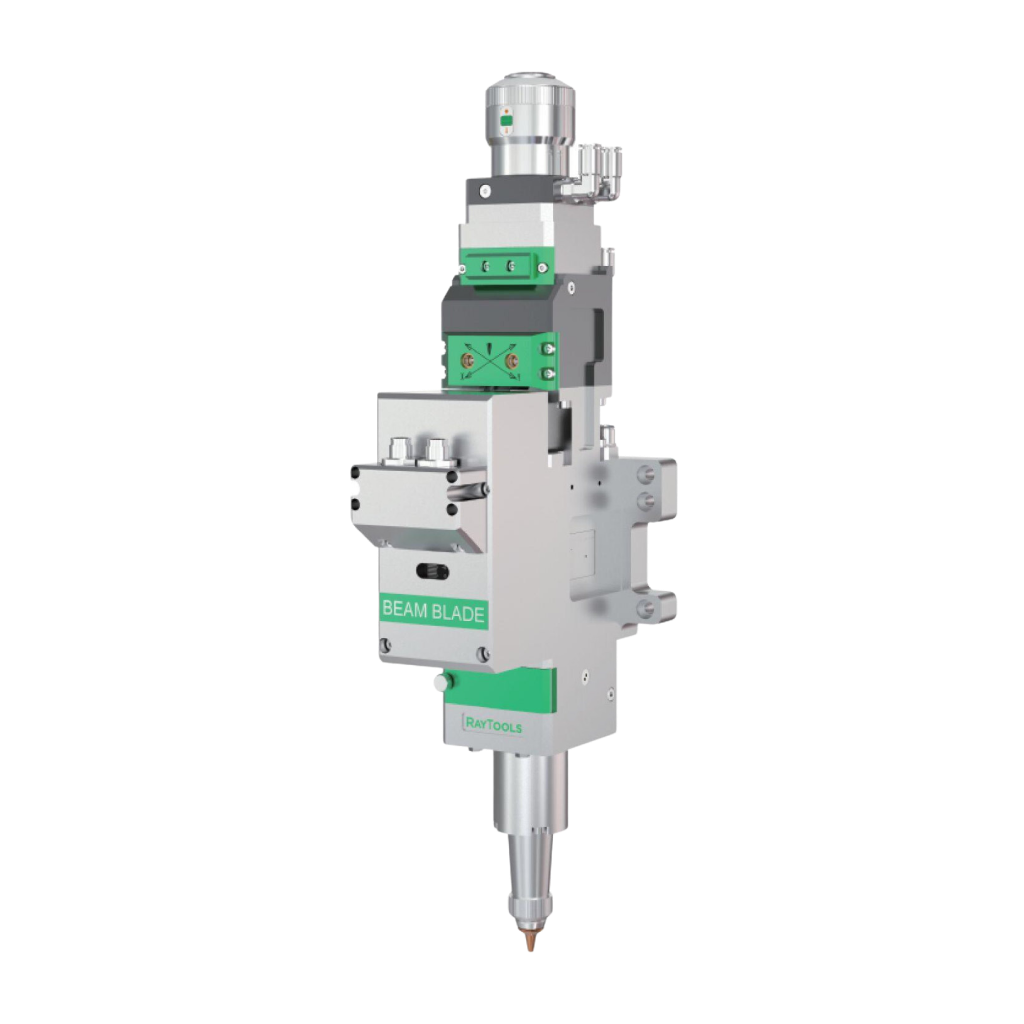

Switzerland Raytools Laser Head: Applicable to various focal lengths, controlled by the machine tool control system. It improves cutting accuracy by separately setting perforation and cutting focal lengths, and is a world-renowned brand. |

|

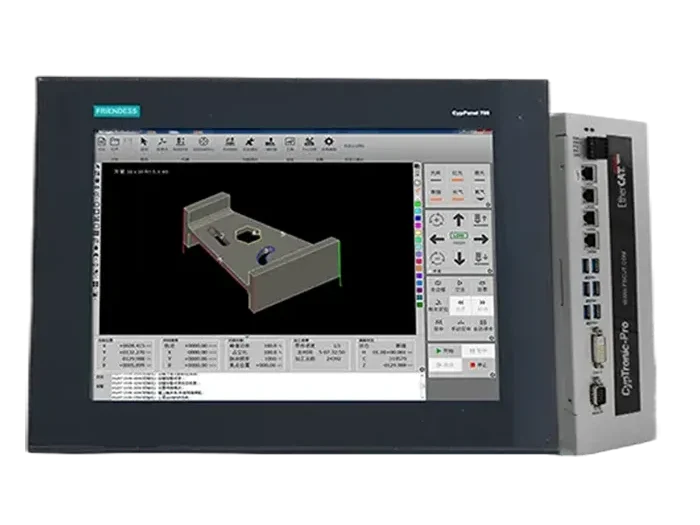

FANGLING Control System: Enables intelligent layout of graphics cutting, automatic optimization of cutting orders, smart edge searching and automatic positioning, enhancing tube utilization with simple and efficient operation. |

|

Water Chiller: Automatically controls the temperature of the laser head and laser source to ensure stable operation of the equipment. |

Technical Parameters

|

Model |

KT6 |

|

Wavelength |

1070nm |

|

Cutting Diameter |

20~220mm ( 350mm 500mm can be option ) |

|

Tube Cutting Length |

6m / 9m / 12m |

|

Laser Power |

1500W / 2000W / 3000W / 6000W / 12000W |

|

X/Y-axis Positioning Accuracy |

0.03mm |

|

X/Y-axis Repositioning Accuracy |

0.02mm |

|

Max. Acceleration |

1.5G |

|

Max. linkage speed |

140m/min |

Introduction:

KT6 metal tube laser cutting machine is mainly used for metal tube cutting . Full servo driving,auto-centering and electric lengthened chuck can save tailings . Cutting area adopts enclosed protection cover, equipped with smoke collection device . Bed roller can effectively support all kinds of diameter tubes in range to ensure cutting accuracy .

Application :

Applicable Materials Of Fiber Laser Tube Cutting Machine

KT6 fiber laser tube cutting stainless steel tube , carbon steel tube , mild steel tube, galvanized steel tube , iron tube , inox tube, aluminium tube , brass tube and other metal tube , metal pipe . Shape can be round tube , square tube , rectangular tube and angle steel etc .

Applicable Industries Of Fiber Laser Tube Cutting Machine

Machinery parts, electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts , furniture and other metal cutting fields.

Sample

Cutting parameters

Cutting parameters

|

Cutting Parameters |

1000W |

1500W |

2000W |

3000W |

6000W |

|

|

Material |

Thickness |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

speed m/min |

|

Carbon steel |

1 |

8.0--10 |

15--26 |

24--32 |

30--40 |

33--43 |

|

2 |

4.0--6.5 |

4.5--6.5 |

4.7--6.5 |

4.8--7.5 |

15--25 |

|

|

3 |

2.4--3.0 |

2.6--4.0 |

3.0--4.8 |

3.3--5.0 |

7.0--12 |

|

|

4 |

2.0--2.4 |

2.5--3.0 |

2.8--3.5 |

3.0--4.2 |

3.0--4.0 |

|

|

5 |

1.5--2.0 |

2.0--2.5 |

2.2--3.0 |

2.6--3.5 |

2.7--3.6 |

|

|

6 |

1.4--1.6 |

1.6--2.2 |

1.8--2.6 |

2.3--3.2 |

2.5--3.4 |

|

|

8 |

0.8--1.2 |

1.0--1.4 |

1.2--1.8 |

1.8--2.6 |

2.0--3.0 |

|

|

10 |

0.6--1.0 |

0.8--1.1 |

1.1--1.3 |

1.2--2.0 |

1.5--2.4 |

|

|

12 |

0.5--0.8 |

0.7--1.0 |

0.9--1.2 |

1.0--1.6 |

1.2--1.8 |

|

|

14 |

|

0.5--0.7 |

0.8--1.0 |

0.9--1.4 |

0.9--1.2 |

|

|

16 |

|

|

0.6-0.8 |

0.7--1.0 |

0.8--1.0 |

|

|

18 |

|

|

0.5--0.7 |

0.6--0.8 |

0.6--0.9 |

|

|

20 |

|

|

|

0.5--0.8 |

0.5--0.8 |

|

|

22 |

|

|

|

0.3--0.7 |

0.4--0.8 |

|

|

Stainless steel |

1 |

18--25 |

20--27 |

24--50 |

30--35 |

32--45 |

|

2 |

5--7.5 |

8.0--12 |

9.0--15 |

13--21 |

16--28 |

|

|

3 |

1.8--2.5 |

3.0--5.0 |

4.8--7.5 |

6.0--10 |

7.0--15 |

|

|

4 |

1.2--1.3 |

1.5--2.4 |

3.2--4.5 |

4.0--6.0 |

5.0--8.0 |

|

|

5 |

0.6--0.7 |

0.7--1.3 |

2.0-2.8 |

3.0--5.0 |

3.5--5.0 |

|

|

6 |

|

0.7--1.0 |

1.2-2.0 |

2.0--4.0 |

2.5--4.5 |

|

|

8 |

|

|

0.7-1.0 |

1.5--2.0 |

1.2--2.0 |

|

|

10 |

|

|

|

0.6--0.8 |

0.8--1.2 |

|

|

12 |

|

|

|

0.4--0.6 |

0.5--0.8 |

|

|

14 |

|

|

|

|

0.4--0.6 |

|

|

Aluminum |

1 |

6.0--10 |

10--20 |

20--30 |

25--38 |

35--45 |

|

2 |

2.8--3.6 |

5.0--7.0 |

10--15 |

10--18 |

13--24 |

|

|

3 |

0.7--1.5 |

2.0--4.0 |

5.0--7.0 |

6.5--8.0 |

7.0--13 |

|

|

4 |

|

1.0--1.5 |

3.5--5.0 |

3.5--5.0 |

4.0--5.5 |

|

|

5 |

|

0.7--1.0 |

1.8--2.5 |

2.5--3.5 |

3.0--4.5 |

|

|

6 |

|

|

1.0--1.5 |

1.5--2.5 |

2.0--3.5 |

|

|

8 |

|

|

0.6--0.8 |

0.7--1.0 |

0.9--1.6 |

|

|

10 |

|

|

|

0.4--0.7 |

0.6--1.2 |

|

|

12 |

|

|

|

0.3-0.45 |

0.4--0.6 |

|

|

16 |

|

|

|

|

0.3--0.4 |

|

|

Brass |

1 |

6.0--10 |

8.0--13 |

12--18 |

20--35 |

25--35 |

|

2 |

2.8--3.6 |

3.0--4.5 |

6.0--8.5 |

6.0--10 |

8.0--12 |

|

|

3 |

0.5--1.0 |

1.5--2.5 |

2.5--4.0 |

4.0--6.0 |

5.0--8.0 |

|

|

4 |

|

1.0--1.6 |

1.5--2.0 |

3.0-5.0 |

3.2--5.5 |

|

|

5 |

|

0.5--0.7 |

0.9--1.2 |

1.5--2.0 |

2.0--3.0 |

|

|

6 |

|

|

0.4--0.9 |

1.0--1.8 |

1.4--2.0 |

|

|

8 |

|

|

|

0.5--0.7 |

0.7--1.2 |

|

|

10 |

|

|

|

|

0.2--0.5 |

|

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine