CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

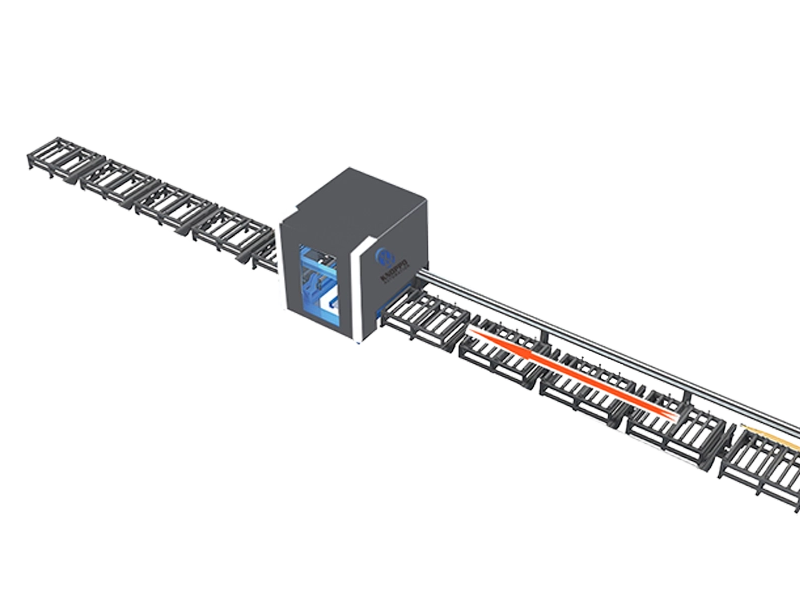

RT400 Automatic H Beam Cutting Beveling Machine

This Profile Plasma Cutting Machine is consisted of cutting unit, roller frame,feeding trolley and rail, finished profile conveying station. It is a hot cutting processing equipment for H beam, I beam, Channel steel, Angle steel, bulb flat and other inter-sectioning shape. Dimension: the max cutting materials is 12000mm , feeding table length can be customized .

Keywords:

Plasma Cutting Machine

Introduction:

This Profile Plasma Cutting Machine is consisted of cutting unit, roller frame,feeding trolley and rail, finished profile conveying station. It is a hot cutting processing equipment for H beam, I beam, Channel steel, Angle steel, bulb flat and other inter-sectioning shape.

Dimension: the max cutting materials is 12000mm , feeding table length can be customized .

This H beam cutting machine is widely used in cutting and processing pipeline structural parts in construction, chemical, shipbuilding, mechanical engineering, metallurgy, electric power and other industries. In the past, most of this kind of processing used backward and complicated operation techniques such as making prototypes, scribing, manual lofting, manual cutting, and manual polishing. The CNC intersecting line cutting machine can cut and process such workpieces very conveniently. There is no need for the operator to calculate or program. You only need to enter the pipe radius, intersection angle and other parameters of the pipe intersecting system, and the machine can automatically cut the intersecting line of the pipe. Intersecting line holes and welding grooves. The CNC pipe intersecting line cutting machine adopts digital control, and the equipment [the number of control axes is two to six axes and other different models. Each model realizes the control axis interlocking during cutting such as working hours, and has the functions of cutting various intersecting lines and intersecting holes; fixed-angle bevel, fixed-point bevel, and variable-angle bevel cutting functions; pipe cutting compensation function

|

Adaptable to Various Profiles and Processing Needs: Efficiently processes multiple profiled materials such as H-beams, I-beams and channel steels, supporting fixed-length straight and oblique cutting, with a maximum cutting length of 12000mm and customizable feeding table length. |

|

High Precision and Flexible Bevel Cutting Capacity: Features ±45° bevel cutting (including fixed-angle, fixed-point and variable-angle), with a length cutting precision of ±1.5mm, supporting plasma (1-45mm) and flame (<60mm) cutting. |

|

Automated Operation for Simplified Processes: No manual programming required; automatically cuts intersecting lines and bevels upon parameter input, with 2-6 axis linkage ensuring precision, replacing traditional complex procedures. |

Strong Industry Applicability and Load-Bearing Capacity:

Widely used in construction, shipbuilding and other industries, capable of cutting profiles up to 5000kg, handling heavy workpiece processing.

Application Areas

|

|

|

|

|

|

|

|

Name | Parameters |

|

Working area |

H beam/I beam/Channel Steel/Angle steel Beam |

600mm - 1500mm |

|

Cutting method |

Plasma/Flame | |

|

Effective cutting length |

12m | |

|

Profile cutting form |

Fixed length straight cut, fixed length oblique cut | |

|

Applicable materials |

Carbon structural steel, stainless steel | |

|

Cutting |

Plasma power source |

200A |

|

method |

Plasma cutting thickness |

Pierce cutting thickness 1 - 45mm |

|

Oxy fuel cutting thickness |

Vertical cutting thickness < 60mm | |

|

Beveling cutting |

±45° | |

|

Machine accuracy |

Cutting precision in length |

±1.5mm |

|

Cutting speed |

10 ~ 2000mm/min | |

|

Moving speed |

10 ~ 6000 mm/min | |

|

Axis |

Robot axis |

X Axis:the cutting torch movement left and right Y1 Axis&Y2 Axis: True bilateral synchronization axis : the cutting torch movement forward and back A Axis:the cutting torch rotation B Axis:the cutting torch yawing C Axis:the external workpiece is to the horizontal feeding Z Axis:the cutting torch up and down |

|

Weight |

Maximum profile weight to be cut |

5000kg |

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine