CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

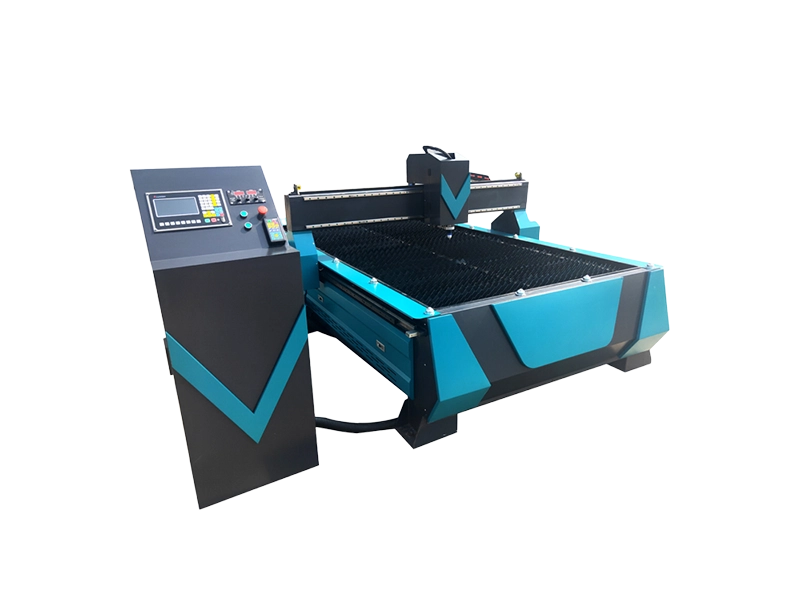

D3015 Single Table Plamsa Cutting Machine

D3015 CNC plasma cutting machine is mainly used for metal sheet cutting . 65A , 100A , 120A , 160A , 200A power is available. Good cutting precision with servo motor

Keywords:

Plasma Cutting Machine

Introduction:

D3015 CNC plasma cutting machine is mainly used for metal sheet cutting . 65A , 100A , 120A , 160A , 200A power is available. Good cutting precision with servo motor

|

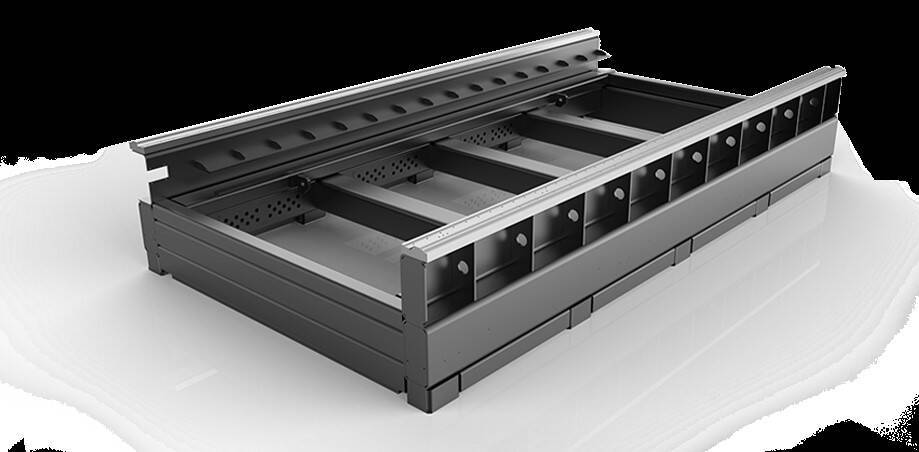

Sturdy and Durable Machine Body: The metal body undergoes 600°C heat treatment, is cooled in the furnace for 24 hours, then processed by a plano-milling machine and welded with carbon dioxide, featuring high strength and a 20-year service life. |

|

High-Precision and Long-Lasting Servo Motor Configuration: Equipped with high precision servo motor, which can improve cutting precision and extend machine lifetime compared to stepper motors used by other brands, with a processing precision of 0.1mm. |

|

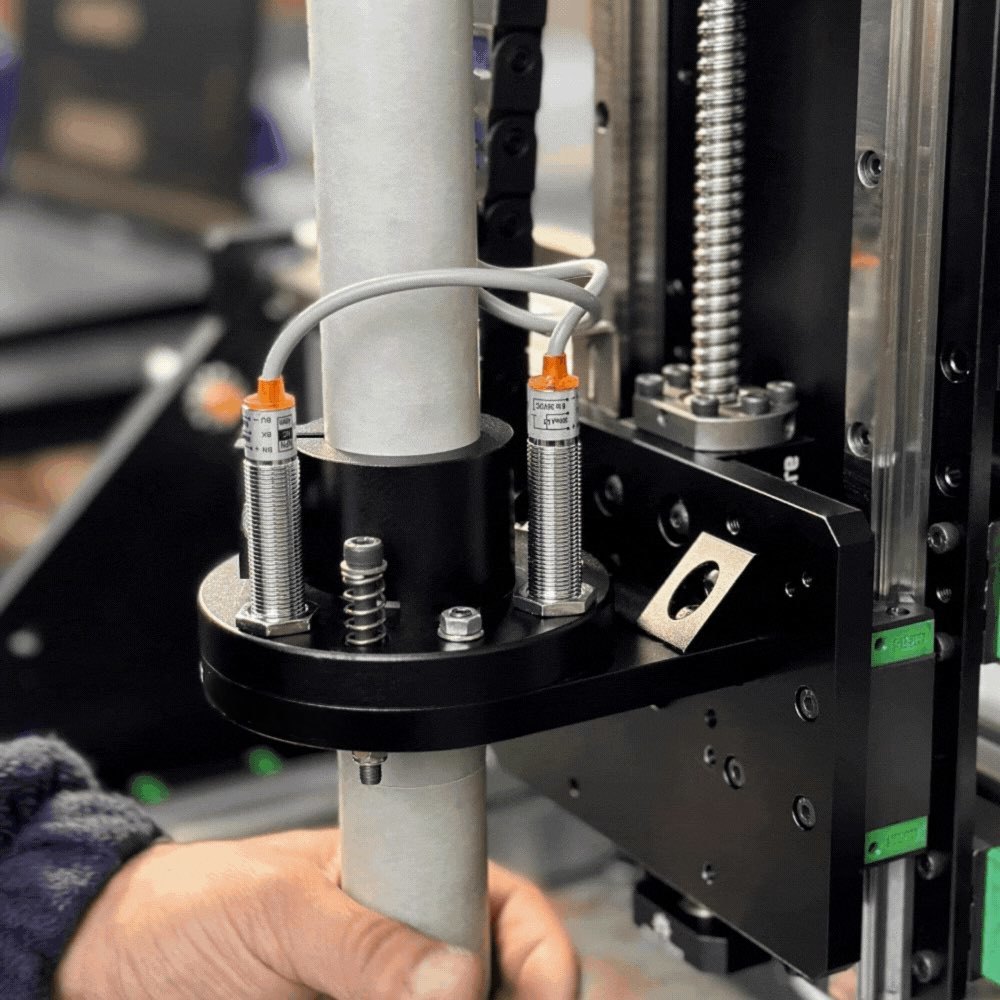

Safe and Reliable Electromagnetic Collision Avoidance Function: Features an electromagnetic collision avoidance function that can effectively protect the cutting head, providing safety guarantees for equipment and operators. |

|

Wide Applicability: Capable of cutting various metal sheets such as stainless steel, carbon steel, alloy steel, etc., and applicable to numerous metal cutting fields including machinery parts, metal arts, electrics, sheet metal fabrication, etc. |

Techinical parameters

|

Model |

D3015 |

|

Plasma power supply |

63A / 100A / 120A / 160A / 200A |

|

Cutting Area |

2500*1300mm / 3000*1500mm /4000*2000mm / 6000*2000mm |

|

Reposition precision |

0.02mm |

|

Processing precision |

0.1mm |

|

Vertical travel of the plasma torch |

300mm |

|

Maximum cutting speed |

12000mm/min |

|

Torch Height control mode |

Automatic |

|

Control system |

STARfire |

|

Software |

Starcam |

|

Electrical Supplier |

380V 50HZ / 3 Phase |

Application

Applicable Materials Of Plasma Cutting Machine

Cutting stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, and other metal sheet, metal plate etc.

Applicable Industries Of Plasma Cutting Machine

Machinery parts, metal arts , electrics, sheet metal fabrication, electrical cabinet, kitchenware, elevator panel, hardware tools, metal enclosure, advertising sign letters, lighting lamps, metal crafts, decoration, jewelry, medical instruments, automotive parts and other metal cutting fields.

Configuration

Stronger Machine Body:The metal body on this cutter has undergone a 600°C heat treatment, and is cooled inside the furnace for 24 hours. After this is complete, it is processed using a plano-milling machine and welded using carbon dioxide. This ensures it has a high strength and a 20 year service life.

Servo Motor , Good Precision and Quality:Servo motor can improve cutting precision and machine lifetime, other brand is still using stepper motor.

Electromagnetic Collision Avoidance Function:This function can protect cutting head, very safe for metal cutting and worker.

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine