CONTACT US

Tel: 86-18663717059

E-Mail: info@knoppoauto.com

WhatsApp: 86-18663717059

Add: 2-804, Fenghuang road, Jinan, Shandong, China

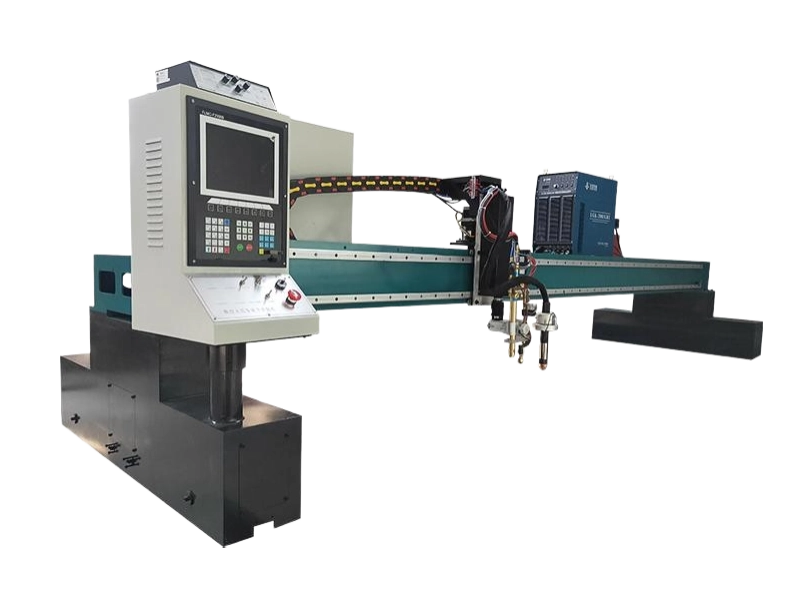

D12 Gantry Type Plasma&Flame Cutting Machine

We have detailed teaching video for customer, like step by step and hand by hand to teach how to use machine and software .etc, so even a freshman will learn machine using faster and easier. While most other factory only have word instructions, we met many customer misunderstand when read the word instruction and lead to operate wrong and damage the machine.

Keywords:

Plasma Cutting Machine

|

Novice-Friendly Teaching and Operation Support: Provides detailed step-by-step teaching videos and multi-language interfaces (English, Russian, Spanish, etc.), significantly lowering the learning curve for beginners compared to competitors with only written instructions. |

|

Long-Lasting Anti-Rust and Durable Design: Machine body undergoes professional anti-rust treatment (two coats of anti-rust paint + topcoat) and uses ultra-soft shielded cables (1.5 million bends), ensuring long-term stability with a 2-year warranty (most competitors offer 1 year). |

|

Intelligent Software Enhances Efficiency and Safety: Software features automatic adjustment (real-time path correction for sheet displacement), automatic nesting of drawings to reduce waste and time; includes 2GB built-in design library for instant use. |

|

Comprehensive Services and Reliable Protection: Pre-sales support (free sampling, factory visits) and after-sales 24/7 technical assistance (remote guidance, overseas engineer service); heavy-duty export wooden crates ensure safe transportation. |

A : The structure and configuration list

|

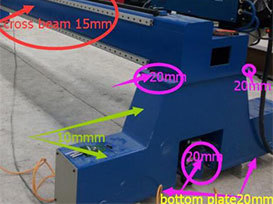

1.Mechanical design heavy fuselage |

7.Starcam software from Australia |

13.Multi-function tool box |

|

2.2500*6000mm work area |

8.High precision Square guide rail |

14.All the necessary parts for machine working |

|

3.LGK160A plasma source |

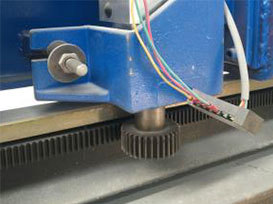

9.Rack and Gear transport system |

15.Planetary reducer |

|

4.Flame cutting system(autoignite) |

10.Stepper motor |

16.3 sets of nozzle electrodes |

|

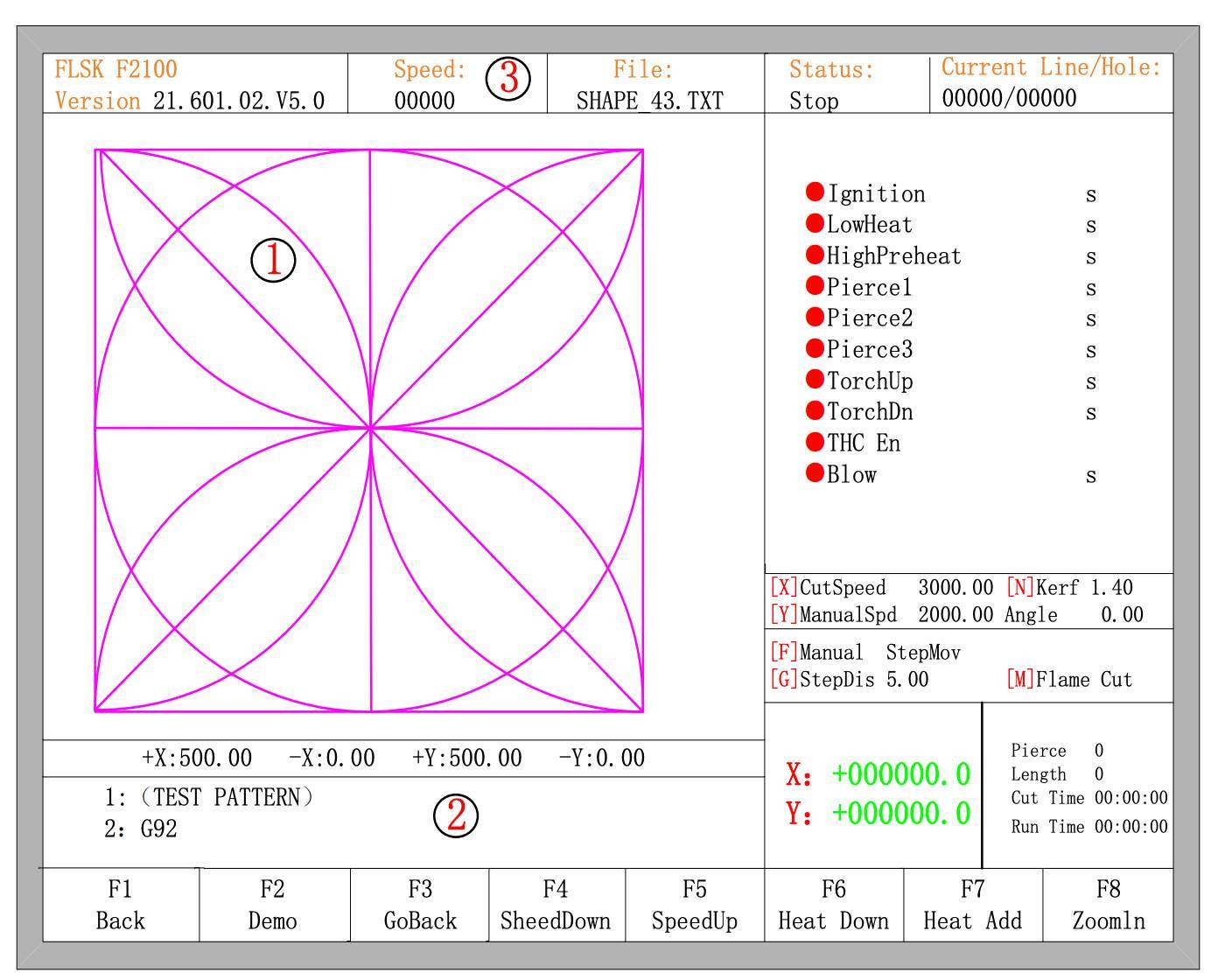

5.SJTU-CNC control system |

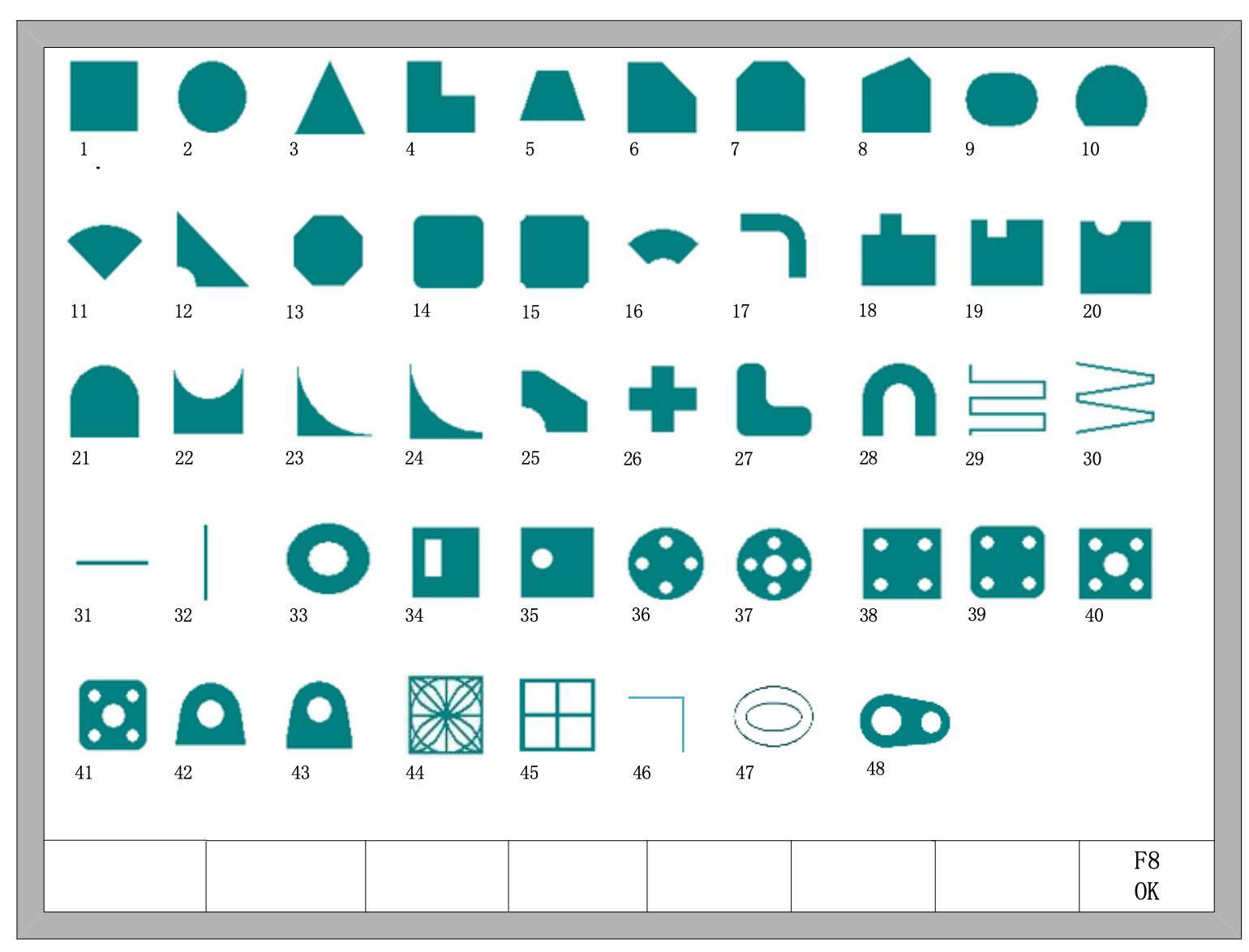

11.2GB ready program |

17.High quality soft electricity cable can be bend for 1.5 million times |

|

6.Automatic torch height control |

12.Detailed teaching video |

B:Machine parts

|

2560 160A plasma cutting machine (high configuration) |

|||

|

LGK160A plasma source |

SJTU-CNC control system | Automatic Torch height control | starcam software |

|

|

|

|

|

|

flame cutting |

Heavy duty Machine body | Lateral drive control system | 2G processing file |

|

|

|

|

|

|

Stepper motor |

Planetary reducer | Rack and gear | Standard export wooden case |

|

|

|

|

|

C : The Technical parameter

|

Model |

2560 |

|

X,Y working area |

2500*6000mm |

|

Z working area |

150mm |

|

Lathe bed |

Very thick steel structure |

|

Machine Power |

8.5kw |

|

Working voltage |

380V/50HZ three phase |

|

Reposition precision |

0.02mm |

|

Processing precision |

0.1mm |

|

Maximum cutting speed |

12000mm/min |

|

Torch Height control mode |

Automatic high sensitive THC |

|

Plasma power supply |

LGK160A |

|

Cutting thickness |

Max35mm carbon steel for plasma, max 250mm carbon steel for flame |

|

Control system |

SJTU-CNC control system |

|

Motors |

Stepper motor |

|

Software |

Starcam |

|

Weight |

1600 KGS |

|

Plasma Air Pressure |

Max.0.8Mpa |

|

Working Temperature |

-10°C-60°C. Relative Humidity, 0-95%. |

|

flame cutting |

250mm |

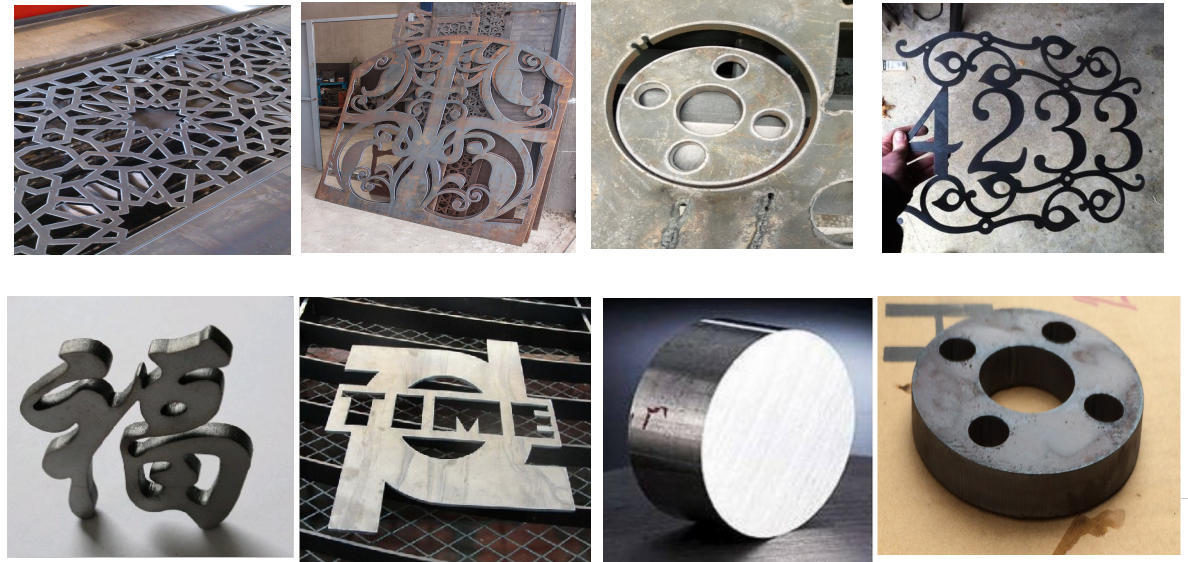

D : The sample photos

E : The advantages of our machine

1. We have detailed teaching video for customer, like step by step and hand by hand to teach how to use machine and software .etc, so even a freshman will learn machine using faster and easier. While most other factory only have word instructions, we met many customer misunderstand when read the word instruction and lead to operate wrong and damage the machine.

2. The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

3.Software: our software have self-adjust function. That means, when you put the metal sheets slide, the software will adjust the cutting according to metal sheets direction, so that it will protect the metal sheets and good cutting results. Especially when cut large or expensive metal sheets, this will preventing big loss. While other factory machine does not have this function.

4.Our machine support many languages, like English, Russia, Spanish etc. Then the clients can operate the machine more convenient

5.When cutting many drawings, our software can automatically sort and achieve best combination, so that the machine can cut all drawings in shortest time.

6.We use super soft shielded cable to ensure that the plasma power supply does not affect the motor during working.

7.Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2 years, while other factory it is only 1 years.

8.we will free provide 2G processing design, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

F. Why most of the customer finally choose us after compared

1. Mature service:

Pre-Sales Service:Inquiry and consulting support, Free making samples support,View our Factory.

After-Sales Service:24 hour technical support by email , telephone or online video ,User friendly English manual for machine using and maintaining, Training how to install the machine and use the machine, Engineers available to service machinery overseas.

2. large machine factory and large quantity producing ability, which can satisfy clients’ large order in short time.

3. We adopt the strength export wooden case, for shipping. It is efficiently protect the machine in good situation after long term transportation.

4. We have details video can show every part of the operation, so after you getting the machine ,and operate in time, and we can also totally according your requirement to do the video only for your job

G.Our factory

Shipping & Packaging

Exhibition

Product Inquiry

Please fill in your contact information and your needs, and we will arrange a professional to contact you!

KF3015P Full Covered Single Table Fiber Laser Cutting Machine

KF3015P full covered fiber laser cutting machine meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cut- ting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KF Series Single Table Fiber Laser Cutting Machine

KF3015 open type fiber laser cutting machine is mainly used for metal sheet cutting. 1500W, 2000W, 3000W, 6000W and 12000W ,20KW ,40KW is available.

KF-T Series Dual Used Fiber Laser Cutting Machine

The equipment meets the parts processing requirements of most industries, working accuracy is stable. Selecting the optimal force and supporting structure, the overall mechanical property of equipment is perfect. Adopting cutting-edge optical concept to improve cutting performance. High speed cutting, auxiliary loading and unloading and efficient production reduce labor costs. At present, laser cutting machines have been widely used in electronics, electrical, mechanical hardware, new energy lithium, packaging, solar, LED, automotive and other industries.

KG Series Large Format Fiber Laser Cutting Machine

supports various bevel cutting types, including A-type, V-type, Y-type, X-type, and K-type. One-stop bevel forming reduces costs.

KP Series Full Closed Fiber Laser Cutting Machine

Equipment Features and Safety Advantages: KP Series Full Closed Fiber Laser Cutting Machine (Model KP3015) adopts a laser glass protective cover and a reasonable dust treatment system, which can effectively reduce harm to the human body. Bilateral six-edge sticks realize overall positioning for stronger stability.

Coil feeding trolley、Coil uncoiler、 Feeding mechanism、Leveling feeder、 Fiber laser cutting machine